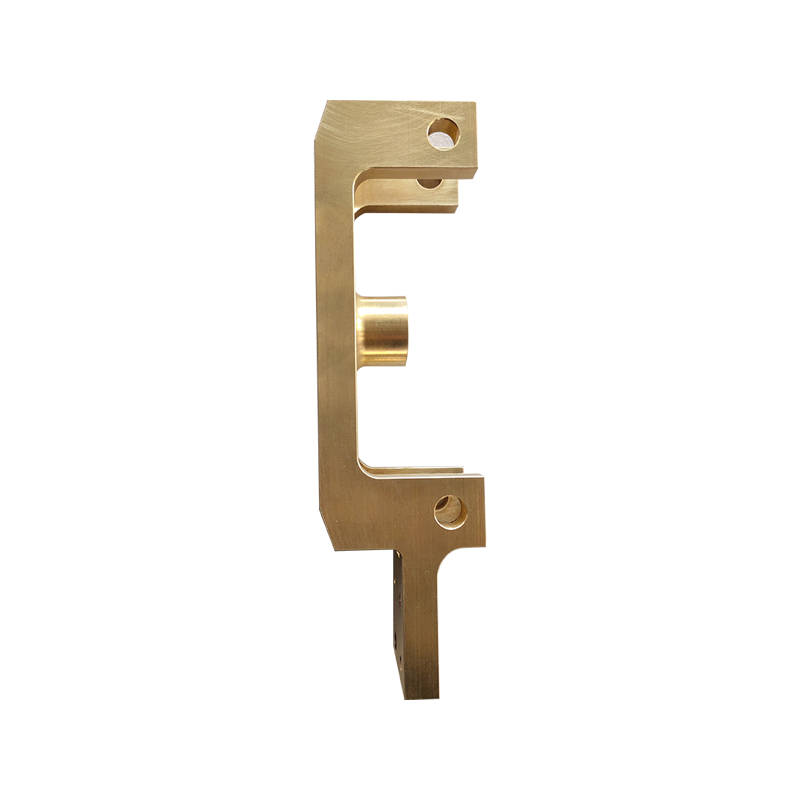

Core advantages:

Super wear resistance: The unique alloy structure of tin bronze greatly reduces the friction coefficient and extends the service life of equipment in ore crushing, transportation and other links.

Corrosion and impact resistance: Resistant to acid, alkali, moisture and dust erosion in the mining environment, while having excellent impact resistance and adapting to high-intensity operations.

High load capacity: High strength combined with good toughness, suitable for key components such as bearings, gears, liners, valves, etc., to ensure stable operation of equipment.

Easy processing and maintenance: Good castability, machinability and formability, support complex parts processing, and reduce later maintenance costs.

Applicable fields:

Open-pit/underground mining equipment, mineral processing machinery, conveying systems, heavy engineering machinery, etc.

Quality Commitment:

Through strict quality control and performance testing, we ensure that each batch of copper plates meets the mining industry standards, provides long-lasting and reliable performance guarantees for equipment, and helps efficient and safe production.

English

English 日本語

日本語 русский

русский Deutsch

Deutsch