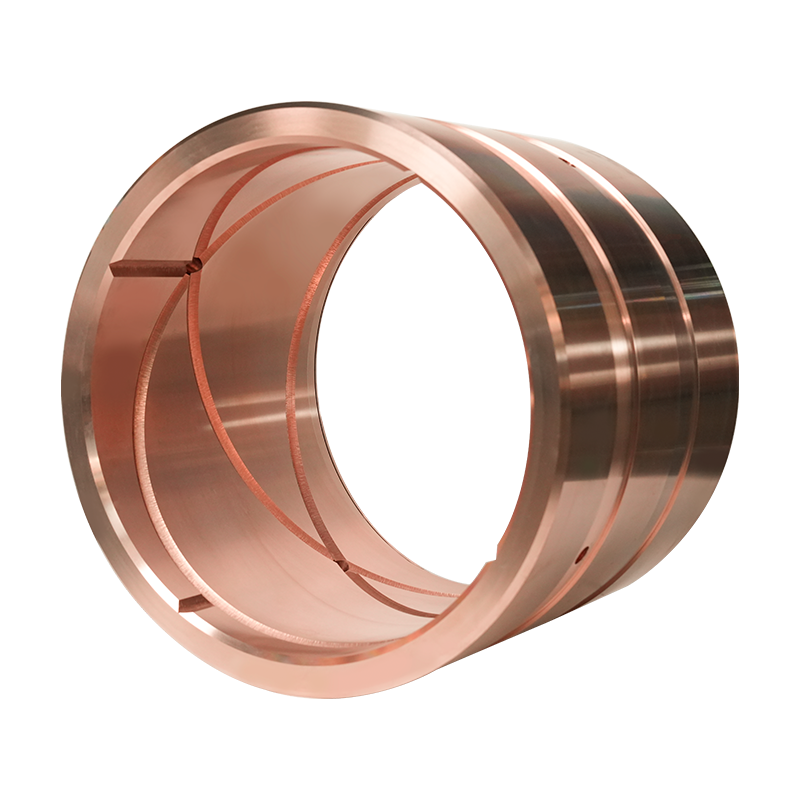

Tin Bronze Bushing For Mining Equipment uses high-purity copper as the base material, and ...

Application Industry

Ship Propulsion And Sealing Device

Ocean drilling and ship lock lifting equipment

Mining equipment

Construction machinery

Oil and gas, metallurgical equipment

English

English 日本語

日本語 русский

русский Deutsch

Deutsch