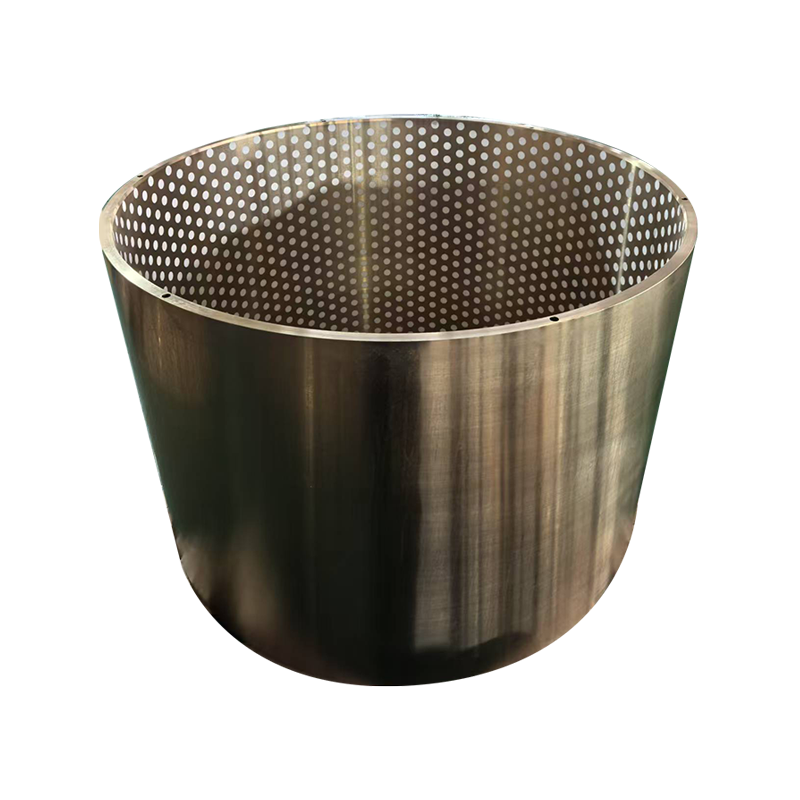

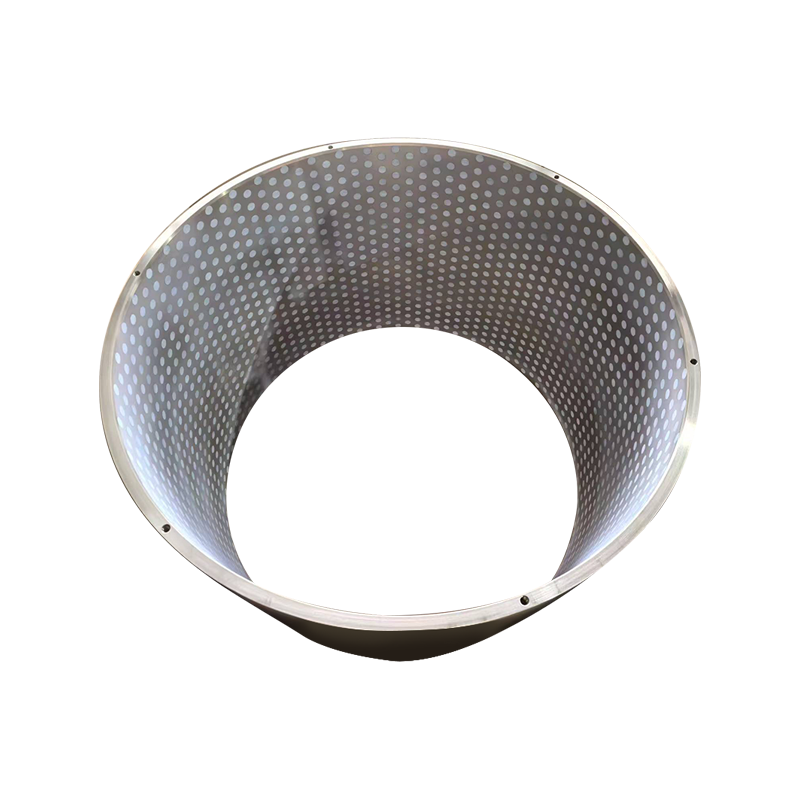

Core advantages

Extreme wear resistance: Made of high-quality brass material, it has excellent pressure resistance and impact resistance, suitable for high-load conditions of engineering machinery, high hardness surface treatment, reduces friction loss and extends the life of the sleeve.

Self-lubricating maintenance-free: Embedded lubrication column continuously releases lubricating medium during operation, reduces friction coefficient, reduces wear, and is suitable for parts that are difficult to lubricate or cannot be regularly filled with lubricating oil, reducing the frequency of downtime maintenance.

Fearless of harsh environment: Resistant to corrosion from seawater, acid and alkali media and humid environments, suitable for complex working conditions such as mines, ports, construction sites, etc., can work stably within extreme temperature ranges and adapt to extreme climatic conditions.

Long life: Compared with traditional copper sleeves, the wear rate is reduced, the replacement frequency is reduced, the equipment operation efficiency is improved, the structure is compact, and the installation is convenient. It is suitable for various types of engineering machinery such as excavators, loaders, cranes, bulldozers, etc.

Applicable to: Engineering machinery, mining equipment, metallurgical equipment, port machinery, agricultural machinery and other heavy-load, low-speed, high-wear working conditions.

English

English 日本語

日本語 русский

русский Deutsch

Deutsch