What Advantages Do Self-Lubricating Brass Bushings Offer?

In demanding industrial environments, bearing performance is critical. Traditional bushings often require frequent manual lubrication, leading to downtime, maintenance costs, and potential failures due to lubrication starvation. Self-lubricating brass bushings present a robust engineering solution, offering distinct advantages in specific applications.

1. Elimination of External Lubrication Requirements:

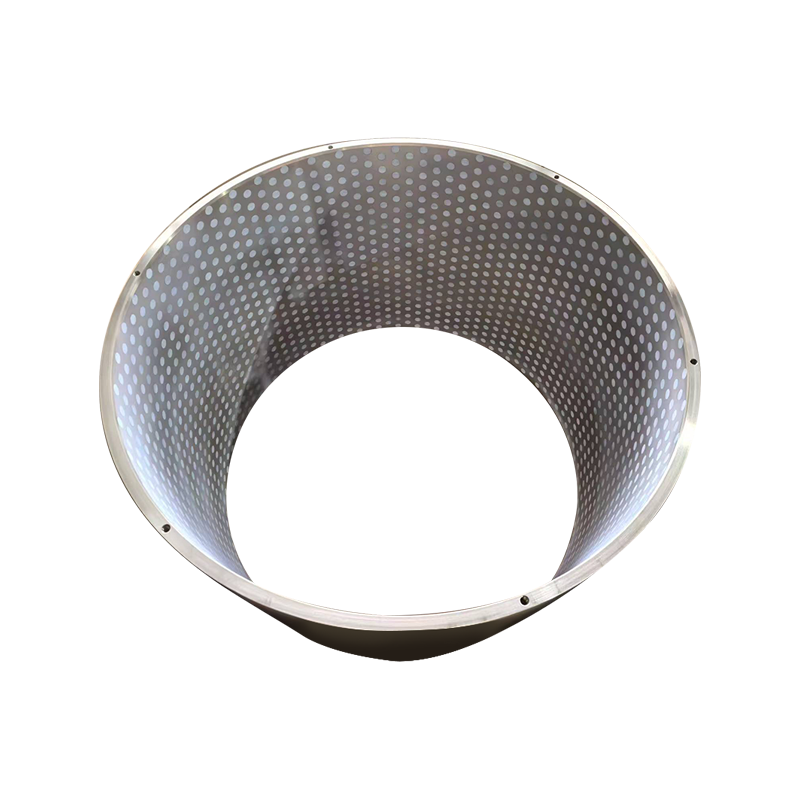

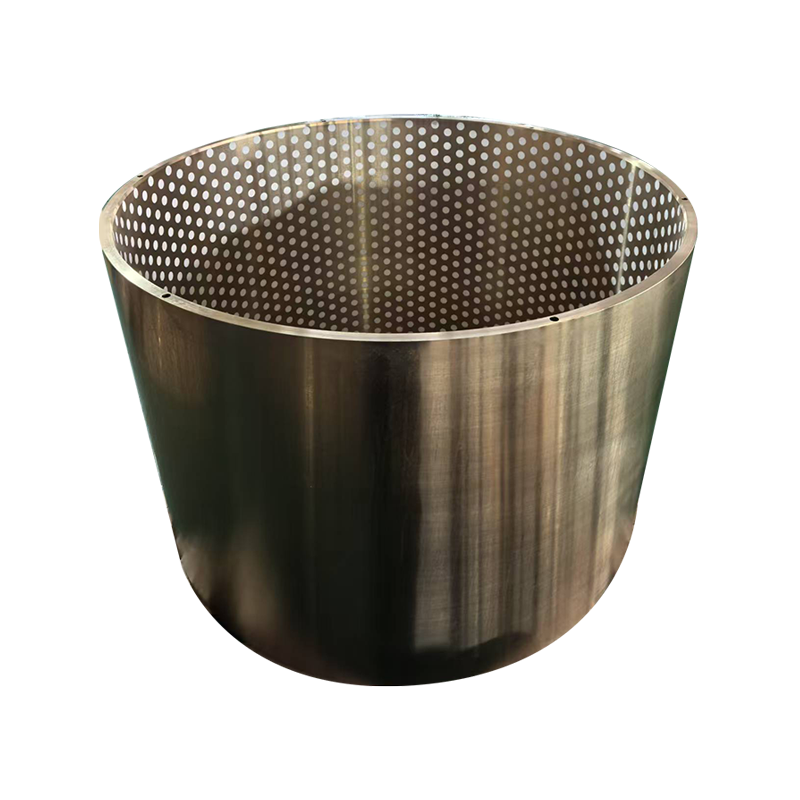

The core advantage lies in their integrated lubrication system. These bushings incorporate solid lubricants (such as graphite, PTFE, or MoS2) uniformly dispersed within the porous brass matrix or embedded in surface grooves. During operation, friction generates heat, causing the lubricants to transfer a thin, consistent film onto the mating shaft surface. This significantly reduces or entirely eliminates the need for periodic external grease or oil application.

2. Enhanced Reliability in Challenging Environments:

Contamination Resistance: In dirty or dusty settings (e.g., mining equipment, metallurgical machinery), external lubricants can attract abrasive particles, accelerating wear. Self-lubricating brass bushings are inherently less susceptible to this failure mode.

Extreme Positions & Sealed Systems: Applications like ship lock lifting systems or sealed compartments within offshore drilling platforms, where manual lubrication points are difficult or impossible to access, benefit immensely from the autonomous lubrication feature.

High/Low Temperature Stability: Quality self-lubricating brass bushings maintain effective lubrication across a wider temperature range than some greases or oils, which can degrade, solidify, or become too thin.

3. Reduced Maintenance Costs and Downtime:

By removing the necessity for scheduled lubrication stops, these bushings directly contribute to lower maintenance labor costs and increased machine availability. This translates to higher productivity and reduced operational disruption, a crucial factor in continuous process industries like oil and gas or mineral processing.

4. Consistent Performance and Wear Reduction:

The continuous transfer of lubricant ensures a more consistent lubricating film compared to the intermittent application typical of manual methods. This consistency minimizes direct metal-to-metal contact, leading to lower friction coefficients, reduced wear on both the bushing and the shaft, and extended component service life.

5. Corrosion Resistance of Brass:

The brass matrix inherently provides good corrosion resistance, particularly against water and many chemicals. This makes self-lubricating brass bushings highly suitable for marine propulsion and sealing systems, offshore platforms, and other applications exposed to moisture or corrosive atmospheres, where steel bushings might be vulnerable.

6. Load Capacity and Embeddability:

Brass offers good load-bearing capacity and conformability (embeddability). The material can absorb small amounts of foreign particles without catastrophic failure, a valuable trait in harsh industrial environments.

Applications Suited for Self-Lubricating Brass Bushings:

These advantages make them particularly well-suited for:

Mining and quarrying equipment (conveyors, crushers, screens)

Marine applications (propulsion shaft bearings, rudder stocks, deck machinery)

Offshore drilling platforms (cranes, winches, lifting systems)

Ship lock and sluice gate lifting mechanisms

Metallurgical machinery (rolling mills, furnaces)

Oil and gas equipment (valves, pumps, compressors in remote locations)

Agricultural machinery

Applications with limited access for maintenance.

Manufacturing Considerations:

The performance of self-lubricating brass bushings depends heavily on material quality and manufacturing precision. Reputable manufacturers, such as Yangzhou Yifeng Copper Products Co., Ltd., specialize in producing high-end copper alloy components. Companies like Yifeng utilize specific brass alloys and controlled processes to ensure uniform lubricant distribution, optimal porosity, dimensional accuracy, and the necessary mechanical properties required for demanding sectors like mining, marine, offshore, and heavy industrial machinery.

Self-lubricating brass bushings offer a compelling engineering solution where reliability, reduced maintenance, and operation in challenging environments are paramount. Their ability to provide consistent internal lubrication, combined with the inherent strength and corrosion resistance of brass, makes them a critical component in extending equipment life and improving operational efficiency across numerous heavy industries. When selecting these bushings, partnering with experienced manufacturers who understand the material science and application demands is essential for optimal performance. Engineers should evaluate specific load, speed, temperature, and environmental conditions to determine suitability.

English

English 日本語

日本語 русский

русский Deutsch

Deutsch