Self-lubricating bushings are critical components in machinery where conventional lubrication is impractical, inaccessible, or prone to contamination. Choosing the right bushing significantly impacts equipment longevity, reliability, and maintenance costs.

1. Define Application Parameters Precisely:

* Load Conditions: Quantify static, dynamic, and shock loads (radial and axial). Consider peak loads and load cycles.

* Speed: Determine rotational or oscillating speed (RPM or frequency). High speeds often require materials with lower friction coefficients.

* Motion Type: Identify continuous rotation, oscillation, or intermittent motion. Oscillating motion is particularly demanding on lubrication retention.

* Environment: Detail operating temperature range, exposure to chemicals (acids, alkalis, solvents), saltwater, dust, abrasive particles, or vacuum conditions.

* Lubricant Compatibility: Assess if external lubricants (grease, oil) are present or prohibited. Some self-lubricating materials perform best dry, while others can work synergistically with minimal external lubrication.

2. Material Selection Based on Performance Needs:

Self-lubricating bushings derive their properties from composite materials. Key types include:

* Metal-Backed Polymer Liners: Common liners include PTFE (low friction, chemical resistance), PTFE compounds (improved wear, PV limit), POM (good wear, moisture resistance), and PA (toughness). Steel or bronze backings provide structural support and heat dissipation. Ideal for moderate loads and speeds across various environments.

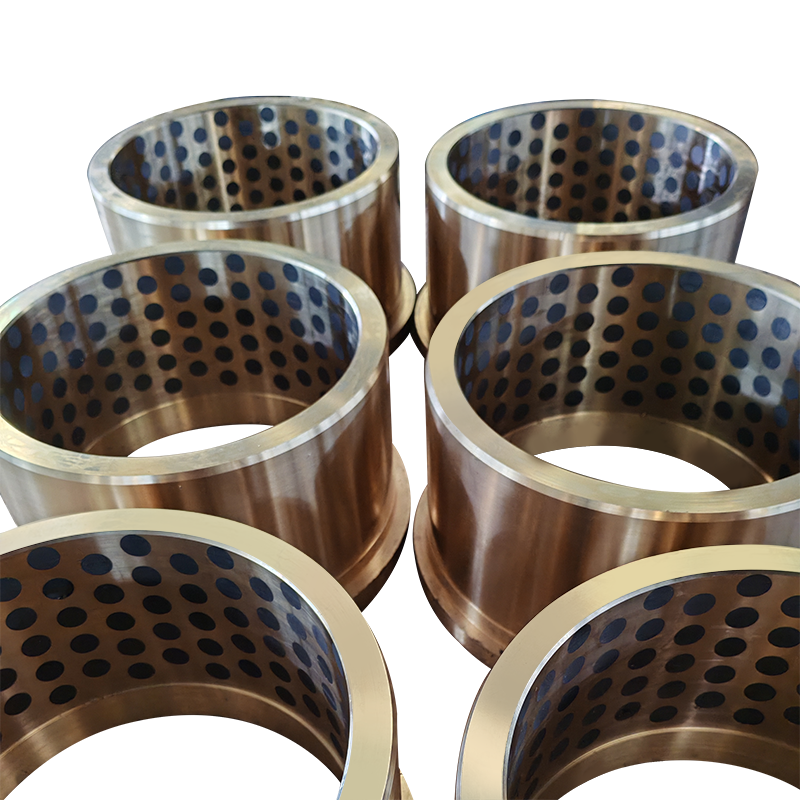

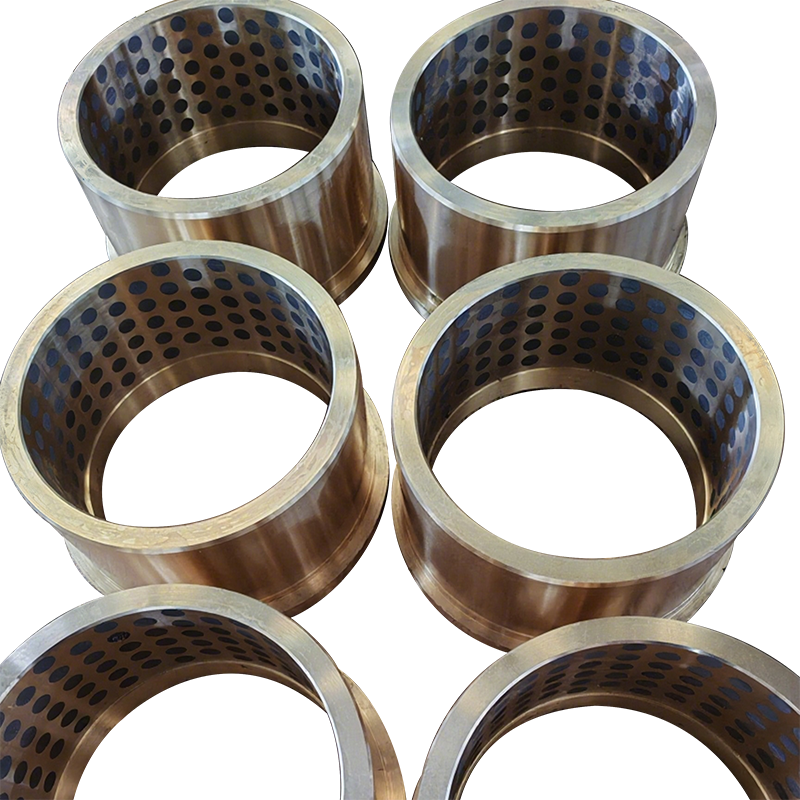

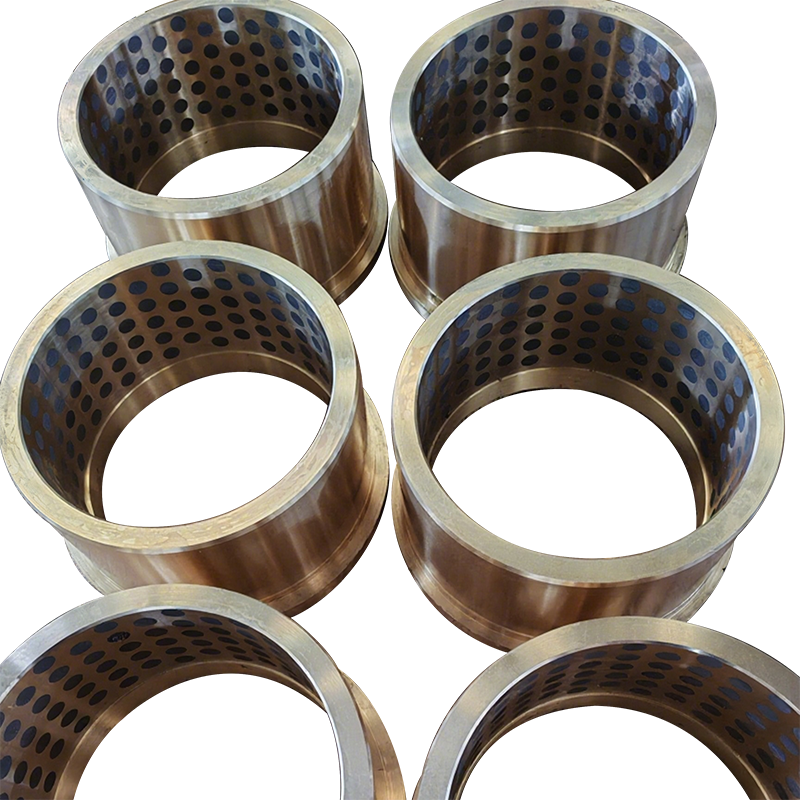

* Sintered Bronze with PTFE/Oil Infusion: Offer high load capacity and good impact resistance. The porous bronze structure is impregnated with lubricants (PTFE, oil, or combinations). Effective in dirty environments where lubricants might be replenished from the matrix. Common in automotive and industrial applications.

* Solid Polymer Bushings: Made from reinforced thermoplastics or thermosets (e.g., PEEK, PI, reinforced nylon). Used where high corrosion resistance or electrical insulation is needed, often for lighter loads.

* Specialty Composites: Include graphite/metal, advanced polymer composites, or custom formulations for extreme conditions (e.g., very high temperatures, ultra-high vacuum, extreme chemical exposure).

3. Critical Material Properties to Evaluate:

* PV Limit (Pressure x Velocity): The maximum permissible product of bearing pressure (P) and sliding velocity (V) before excessive wear or failure occurs. Exceeding the PV limit is a primary cause of premature bushing failure.

* Coefficient of Friction (CoF): Impacts energy efficiency, heat generation, and stick-slip tendency. Lower CoF is generally desirable but must be balanced with wear resistance.

* Wear Rate: Determines service life under specific operating conditions. Evaluate against expected load, speed, and environment.

* Load Capacity (Static & Dynamic): Ensure the material can withstand both peak static loads and continuous operational dynamic loads without deformation or excessive wear.

* Temperature Range: Verify the material retains its properties (strength, lubricity) across the application's operating temperature extremes.

* Corrosion & Chemical Resistance: Essential for marine, chemical processing, or mining applications exposed to harsh substances.

* Thermal Conductivity: Influences heat dissipation; metal-backed bushings generally offer better heat dissipation than solid polymers.

4. Consider Dimensional Tolerances and Installation:

* Ensure precise housing bore and shaft dimensions according to manufacturer specifications for proper interference fit and optimal performance.

* Follow recommended installation procedures to avoid damaging the liner or bushing structure. Improper installation is a frequent cause of early failure.

5. Compliance and Certification:

* Verify if the self-lubricating bushing meets relevant industry standards (e.g., ASTM, ISO, DIN) or specific certifications (e.g., FDA, marine approvals) required for your application.

6. Leverage Manufacturer Expertise:

Reputable manufacturers specializing in high-performance applications possess deep material knowledge and application experience. Companies like Yangzhou Yifeng Copper Products Co., Ltd., focusing on sectors like mining equipment, marine propulsion, oil and gas, offshore drilling, and ship lock systems, develop self-lubricating bushings specifically engineered for extreme environments. Consulting their technical teams during the selection process is highly recommended, especially for critical or non-standard applications. Provide them with detailed application data for precise recommendations.

Selecting the optimal self-lubricating bushing requires a systematic analysis of the application's mechanical, environmental, and operational demands. Prioritizing key material properties like PV limit, wear rate, load capacity, and environmental resistance is paramount. By carefully matching these requirements to the capabilities of specific self-lubricating composite materials and leveraging manufacturer expertise, engineers can ensure reliable, long-lasting performance and minimize costly downtime in demanding industrial settings.

English

English 日本語

日本語 русский

русский Deutsch

Deutsch