Where is Tin Bronze Alloy Plate commonly used in industry?

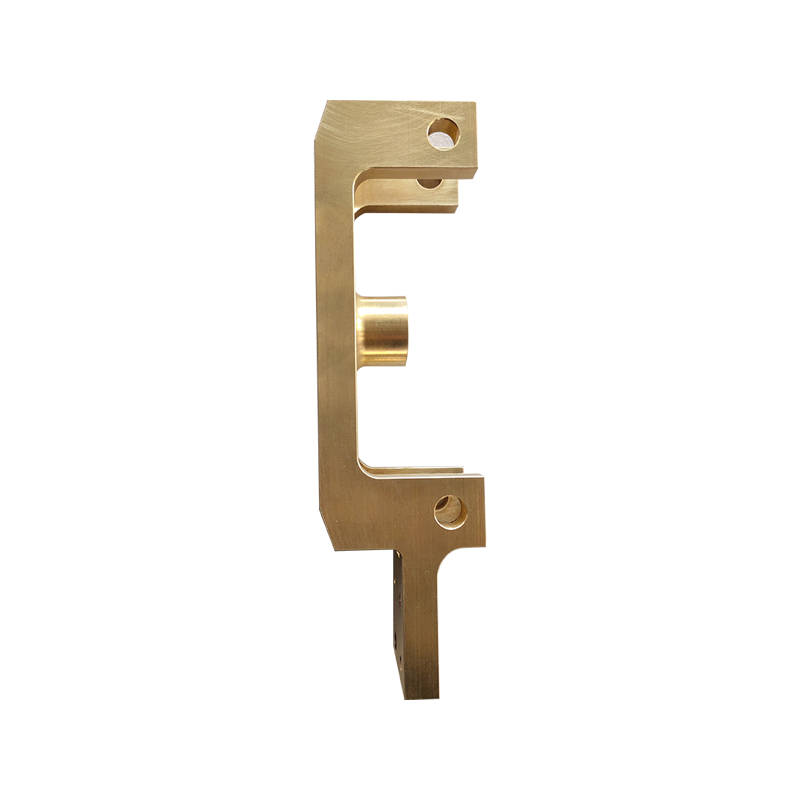

Tin Bronze Alloy Plate, characterized by its exceptional combination of strength, wear resistance, corrosion resistance, and low friction properties, is a critical material across diverse demanding industrial sectors. Its unique composition, primarily copper with tin and often minor additions like phosphorus or zinc, makes it indispensable where reliability under harsh conditions is paramount.

Key Industrial Uses of Tin Bronze Alloy Plate:

Mining & Mineral Processing Equipment: The high wear resistance and ability to withstand shock loading make Tin Bronze Alloy Plate ideal for components like crusher liners, shovel bushings, and heavy-duty bearing pads. It resists abrasion from ores and rocks, ensuring longevity in this punishing environment. Manufacturers like Yangzhou Yifeng Copper Products Co., Ltd. often supply this material for such mining machinery applications.

Marine Propulsion & Sealing Systems: Tin Bronze Alloy Plate excels in seawater applications due to its excellent resistance to corrosion, biofouling, and dezincification. It is extensively used for wear plates, thrust washers, and bearing surfaces within ship propellers, stern tubes, pumps, and valve components subjected to seawater flow and pressure.

Metallurgical Machinery: The high-temperature strength and stability of Tin Bronze Alloy Plate are crucial in metallurgical settings. It serves effectively as bearing plates, guides, and wear strips in rolling mills, continuous casting machines, and furnace components, where it must endure heat, heavy loads, and abrasive scale.

Oil & Gas Equipment (Onshore & Offshore): Tin Bronze Alloy Plate is vital for components requiring reliability under high pressure, corrosive fluids (including sour service in some grades), and abrasive slurries. Applications include valve stems and seats, pump wear rings, bearing surfaces in drilling equipment, and critical parts within Christmas trees and blowout preventers (BOPs). Its use extends to demanding offshore drilling platform components.

Hydraulic Systems & Heavy Lifting: The low coefficient of friction combined with high compressive strength makes Tin Bronze Alloy Plate the material of choice for wear plates and bushings in massive hydraulic systems. A prime example is its use in ship lock gate lifting mechanisms and sluice gate bearings, where it supports immense loads and constant movement with minimal wear.

General Heavy-Duty Bearings and Bushings: Beyond the sectors above, Tin Bronze Alloy Plate is widely machined into custom bearings, bushings, thrust washers, and wear plates for industrial machinery across power generation, heavy manufacturing, and transportation. It performs reliably in situations involving boundary lubrication or high static loads.

Why Tin Bronze Alloy Plate is Selected:

Superior Wear Resistance: Outperforms many other bronzes and steels in abrasive environments.

High Load Capacity: Maintains integrity under significant compressive and shock loads.

Corrosion Resistance: Performs well in seawater, chemicals, and various industrial atmospheres.

Low Friction & Anti-Galling Properties: Reduces wear on mating surfaces and prevents seizing.

Machinability & Fabrication: Can be readily machined, formed, and joined for complex components.

Conformity to Standards: Available in grades meeting specifications like ASTM B505 (C90300, C90700, C93700 etc.), ensuring consistent quality.

Tin Bronze Alloy Plate remains a cornerstone material for engineers facing challenges involving wear, corrosion, high loads, and critical reliability. Its versatility across industries—from the depths of mines and oceans to the heart of refineries and power plants—stems directly from its proven performance characteristics. Companies specializing in high-end copper alloys, such as Yangzhou Yifeng Copper Products Co., Ltd., focus on supplying precisely engineered Tin Bronze Alloy Plate to meet the stringent demands of these diverse and vital industrial applications. When durability and dependability under pressure are non-negotiable, Tin Bronze Alloy Plate is frequently the engineered solution.

English

English 日本語

日本語 русский

русский Deutsch

Deutsch