How to choose the right Copper Bush?

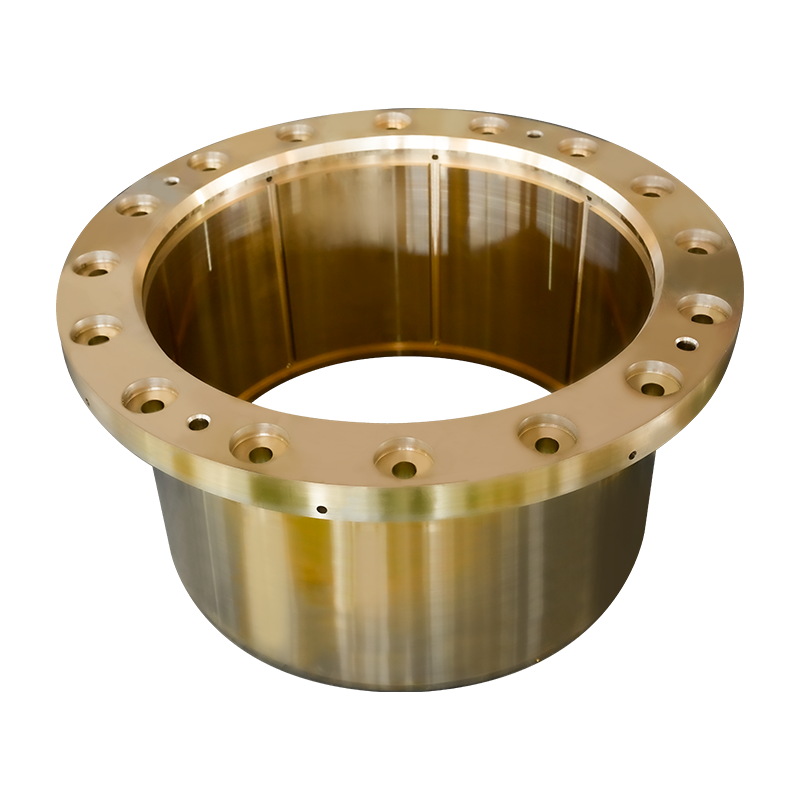

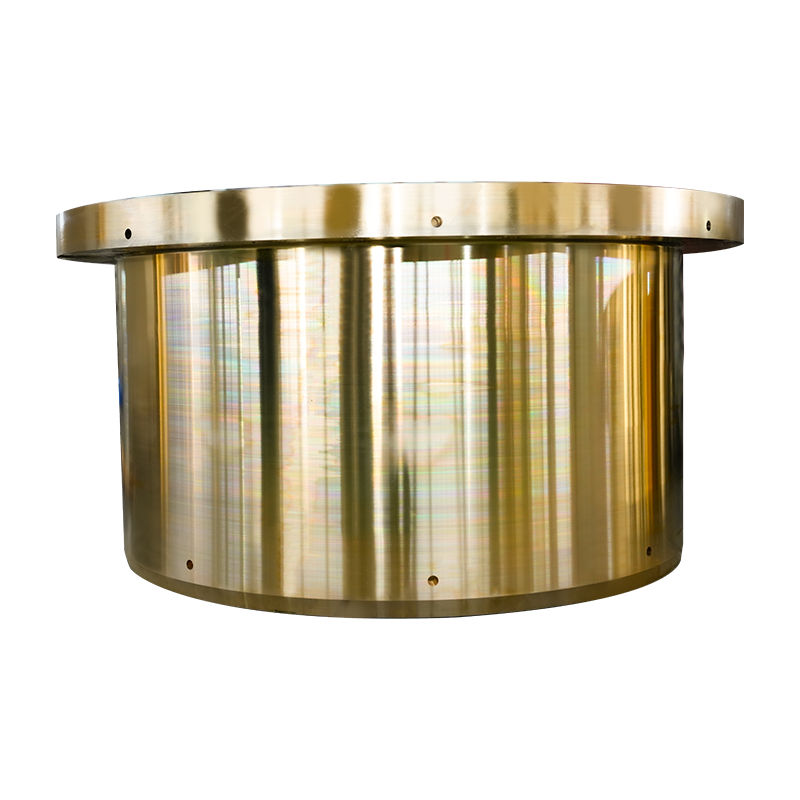

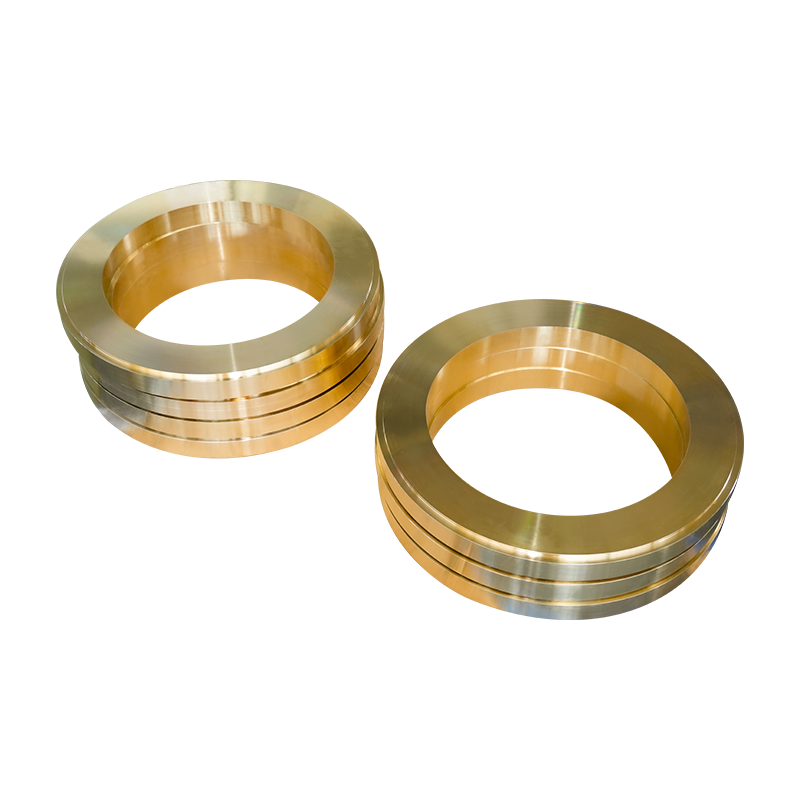

Copper bushes, also known as plain bearings or sleeve bearings, are critical components in countless industrial systems. Their primary role is to reduce friction between moving parts, support rotating shafts, and absorb wear. Choosing the correct Copper Bush is paramount for ensuring machinery longevity, operational efficiency, and minimizing costly downtime.

1. Material Composition: The Foundation of Performance

Bronze Alloys: The most common material for Copper Bush applications. Key types include:

Tin Bronze (e.g., SAE 660 / C93200): Excellent wear resistance, good machinability, and moderate corrosion resistance. Suitable for moderate loads and speeds in general industrial applications (e.g., mining equipment gears).

Aluminum Bronze (e.g., C95400, C95500): Superior strength, exceptional corrosion resistance (especially against seawater and chemicals), and good wear properties. Ideal for demanding environments like marine propulsion and sealing systems, offshore drilling platforms, and highly loaded applications in metallurgical machinery.

Lead Bronze (e.g., SAE 48 / C94300): Offers superior embeddability (traps contaminants) and conformability, along with excellent anti-seizure properties under boundary lubrication conditions. Often used in oil and gas equipment.

High-Leaded Tin Bronze (e.g., SAE 64 / C93700): Combines good wear resistance with excellent machinability and compatibility under poor lubrication. Common in general machinery.

Brass Alloys (e.g., CDA 360): Primarily used for lower-load, low-speed applications where cost is a major factor. Generally inferior in wear resistance and strength compared to bronzes.

2. Dimensional Accuracy and Tolerances

Precise inner diameter (ID), outer diameter (OD), and length are non-negotiable for proper fit and function.

Carefully match the Copper Bush dimensions to the housing bore and shaft specifications.

Adherence to recognized tolerance standards (e.g., ISO, ASTM) is essential. Oversized bushes can cause housing damage during installation, while undersized bushes lead to poor fit and premature failure.

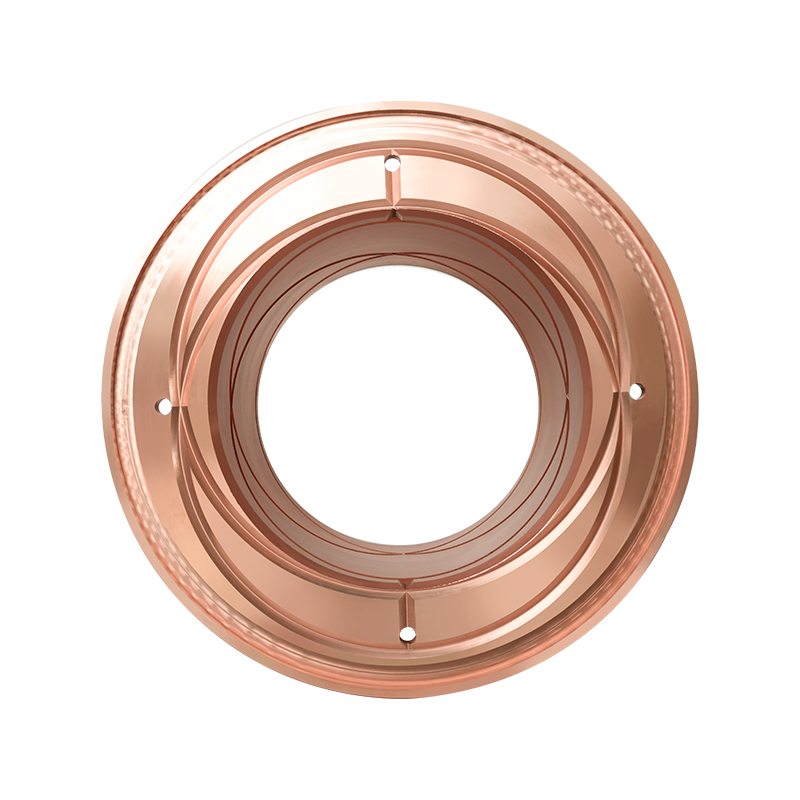

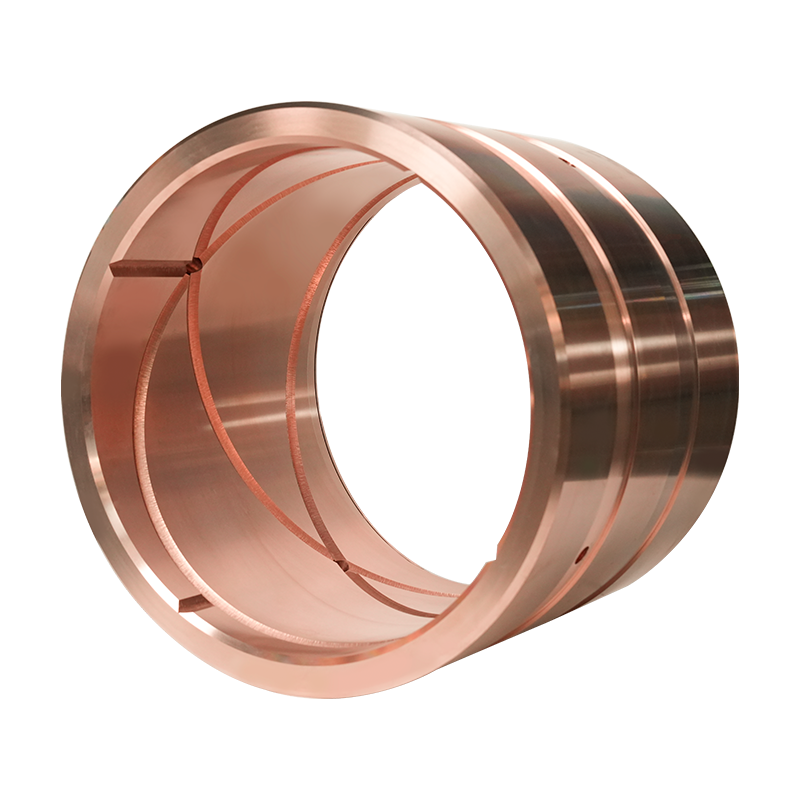

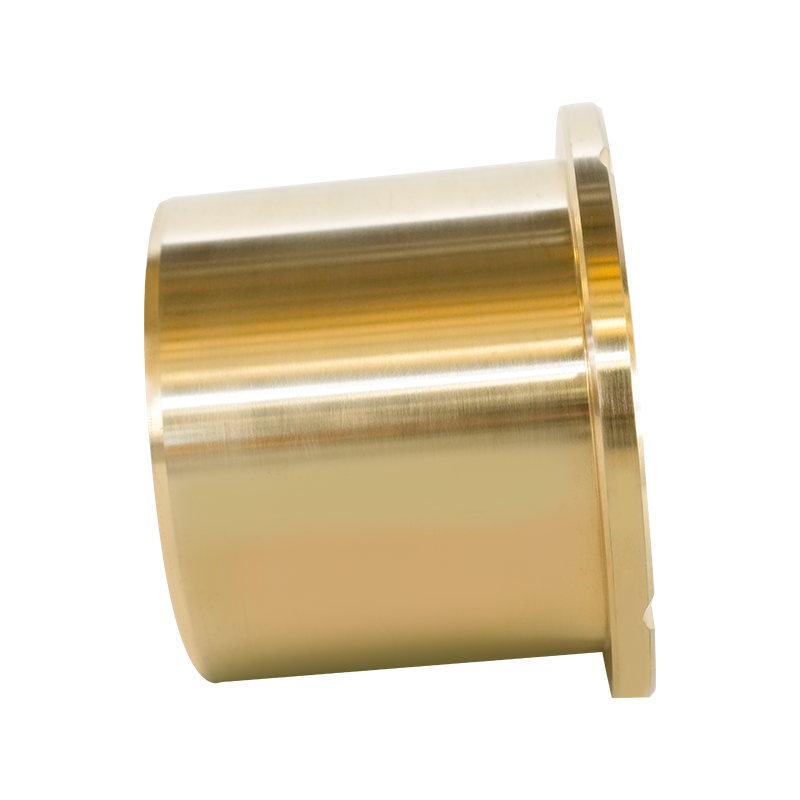

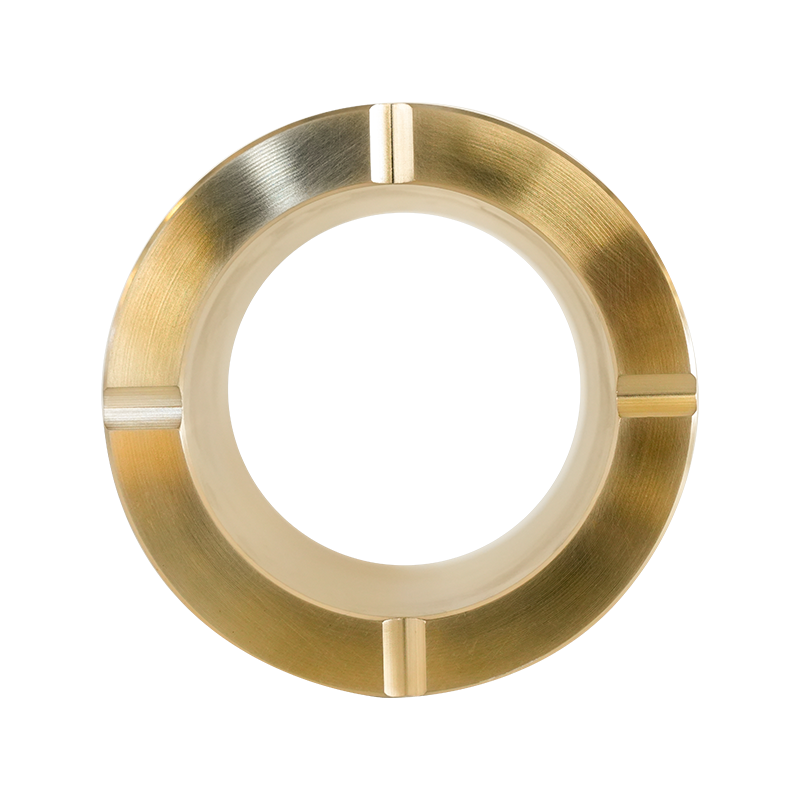

3. Surface Finish and Geometry

A smooth internal bore surface minimizes friction and wear on the shaft.

Consistent wall thickness ensures uniform load distribution and prevents localized stress points.

Features like lubrication grooves (axial, circumferential, spiral), oil holes, flanges, or thrust faces must be specified based on the lubrication method and axial load requirements of the application (common in ship lock lifting systems).

4. Application Conditions: Defining the Requirements

Load (Radial & Axial): Determine static and dynamic loads. High-strength alloys like Aluminum Bronze are necessary for heavy loads.

Speed (RPM): Surface speed impacts heat generation and lubrication needs. Higher speeds often require tighter clearances and reliable lubrication.

Lubrication Regime: Will lubrication be continuous, intermittent, or borderline? Self-lubricating Copper Bush options (e.g., oil-impregnated sintered bronze) exist but have load/speed limitations compared to externally lubricated solid bushes.

Operating Environment: Exposure to moisture, salt spray, chemicals, abrasive dust (common in mining equipment), or extreme temperatures dictates material choice. Aluminum Bronze excels in corrosive environments; Tin Bronze handles abrasives well.

Shaft Material and Hardness: Compatibility between the bush and shaft material is crucial to prevent galling or excessive wear. Generally, the shaft should be harder than the bush.

5. Manufacturing Quality and Standards

Source Copper Bush components from reputable manufacturers adhering to strict quality control processes (e.g., ISO 9001 certified).

Material certifications (e.g., Mill Test Reports) verifying chemical composition and mechanical properties (hardness, tensile strength) are vital.

Look for consistency in casting or forging quality, freedom from porosity, inclusions, or cracks. Precision machining is critical for dimensional accuracy and surface finish.

6. Supplier Expertise and Support

Choose a supplier with demonstrable experience in your specific industry sector (e.g., mining equipment, marine propulsion, oil and gas equipment, offshore platforms, metallurgical machinery).

Technical support capabilities for application engineering and material selection advice are invaluable. Suppliers like Yangzhou Yifeng Copper Products Co., Ltd., specializing in high-end copper alloys for demanding industrial sectors, exemplify the type of technical partner that can ensure optimal Copper Bush performance.

Selection Process Summary:

Analyze Application: Define loads, speeds, environment, lubrication, and shaft details.

Prioritize Material: Select the copper alloy (Bronze type typically) that best meets the performance demands identified in step 1.

Specify Dimensions & Features: Determine exact sizes (ID, OD, length), tolerances, and required features (grooves, holes, flanges).

Verify Quality: Ensure the supplier provides material certifications and adheres to recognized quality standards.

Consult Experts: Leverage the technical expertise of specialized manufacturers for complex applications.

English

English 日本語

日本語 русский

русский Deutsch

Deutsch