How Do Aluminum Bronze Self-Lubricating Bushings Compare to Steel Bushings?

Selecting the optimal bushing material is critical for equipment reliability, performance, and lifecycle cost. Aluminum Bronze Self-Lubricating Bushings and traditional steel bushings represent distinct solutions, each suited to specific operational demands.

1. Material Composition and Base Properties:

Steel Bushings: Typically manufactured from carbon steels, alloy steels (like 4140), or stainless steels (e.g., 304, 316). Offer high inherent strength and hardness, particularly in hardened conditions. Their primary vulnerability lies in corrosion susceptibility (except stainless variants) and the absolute requirement for external lubrication to prevent galling and rapid wear.

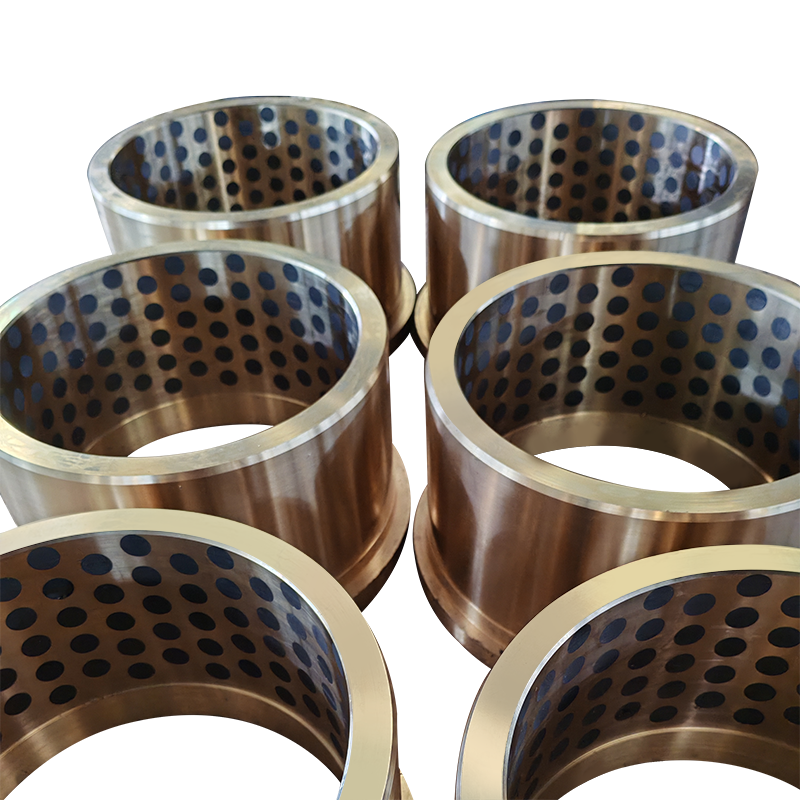

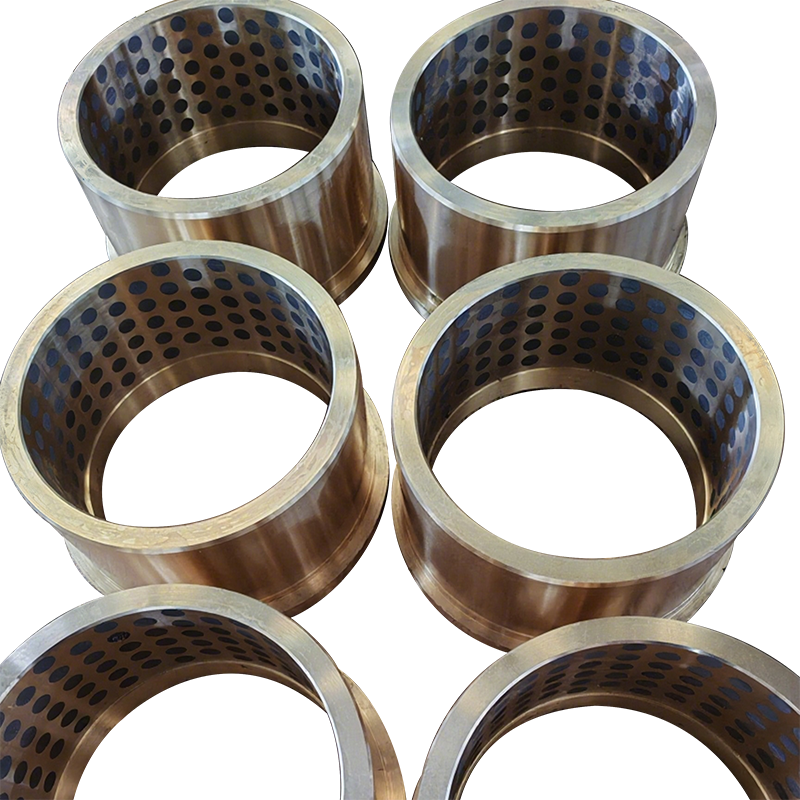

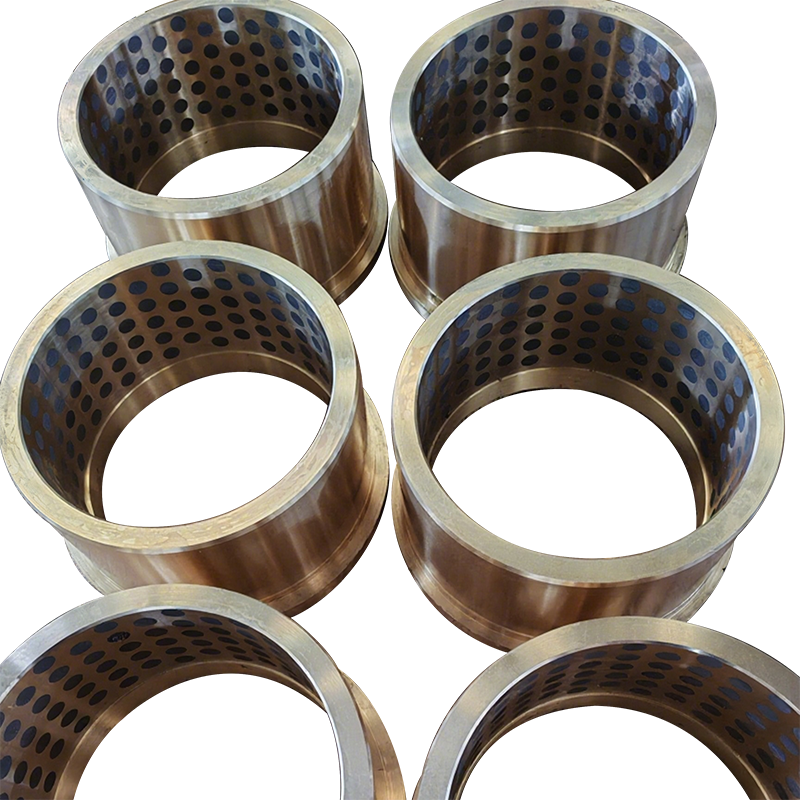

Aluminum Bronze Self-Lubricating Bushings: Composed primarily of copper, with significant additions of aluminum (8-12%) and often iron, nickel, and manganese. This alloy family (e.g., C95400, C95500) inherently possesses high strength (approaching some steels), excellent corrosion resistance, and good fatigue strength. The defining feature is the integration of solid lubricants (typically graphite or PTFE) within a sintered bronze matrix layered onto the aluminum bronze backing.

2. Lubrication Mechanism and Maintenance:

Steel Bushings: Require continuous external lubrication (oil or grease) to function effectively. Failure of the lubrication system leads to catastrophic friction, seizing, and wear. Regular maintenance schedules for re-lubrication are mandatory, increasing operational complexity and cost, especially in hard-to-access locations.

Aluminum Bronze Self-Lubricating Bushings: Engineered to operate with minimal or no external lubrication. Embedded solid lubricants are continuously supplied to the bearing surface during operation, forming a transfer film. This significantly reduces dependency on external lubrication systems, lowers maintenance frequency and cost, and eliminates failures due to lubricant starvation. They are ideal for sealed-for-life applications or environments where lubrication is impractical (e.g., submerged, food processing, high contamination zones).

3. Corrosion and Chemical Resistance:

Steel Bushings: Carbon and alloy steels are highly susceptible to rust and corrosion in wet, humid, or chemically aggressive environments, requiring protective coatings or specific stainless steel grades. Stainless steels offer better resistance but can still suffer from pitting or crevice corrosion and are generally more expensive.

Aluminum Bronze Self-Lubricating Bushings: Aluminum bronze alloys exhibit outstanding resistance to corrosion by seawater, many acids, alkalis, and industrial chemicals. This makes them particularly valuable in marine propulsion and sealing systems, offshore drilling platforms, chemical processing equipment, and ship lock lifting systems – environments where steel bushings often fail prematurely without exceptional protection.

4. Wear Resistance and Load Capacity:

Steel Bushings: Can handle very high static and dynamic loads, especially hardened grades. Wear resistance is heavily dependent on maintaining adequate lubrication and preventing abrasive contamination. Under boundary lubrication conditions, wear can be rapid.

Aluminum Bronze Self-Lubricating Bushings: Offer good load capacity, suitable for many heavy-duty applications. While the base aluminum bronze is strong, the wear resistance under dry or marginally lubricated conditions is superior to standard steel bushings in such scenarios. The embedded lubricants provide inherent protection against galling and seizure. Their performance is often characterized by lower friction coefficients under start-stop conditions.

5. Temperature Performance:

Steel Bushings: Performance depends heavily on the lubricant's temperature limits. Conventional oils and greases can degrade at elevated temperatures (>150°C), leading to failure. Special high-temperature lubricants are required for extreme conditions.

Aluminum Bronze Self-Lubricating Bushings: Capable of operating effectively across a wider temperature range without reliance on liquid lubricants. Solid lubricants like graphite function well at high temperatures (up to 350-400°C in air), making these bushings suitable for applications like furnace equipment or high-temperature machinery components.

6. Application Suitability:

Steel Bushings (Lubricated): Remain the preferred choice for extremely high-load, high-speed applications where continuous, reliable lubrication can be guaranteed, such as in automotive engines or precision machinery shafts.

Aluminum Bronze Self-Lubricating Bushings: Excel in applications demanding low maintenance, corrosion resistance, operation in dirty/dry environments, or resistance to seizure. Key sectors include:

Mining Equipment (exposed to abrasives, shock loads)

Marine Propulsion and Sealing Systems (seawater corrosion)

Offshore Drilling Platforms (salt spray, limited maintenance access)

Metallurgical Machinery (high heat, contamination)

Oil and Gas Equipment (chemical exposure, remote locations)

Hydraulic Systems (where lubricant washout is a concern)

Food and Beverage Processing (sanitary requirements)

Manufacturers like Yangzhou Yifeng Copper Products Co., Ltd. specialize in producing high-performance aluminum bronze components, including self-lubricating bushings. Their focus on alloys such as C95400 and C95500 caters specifically to the demanding environments found in mining, marine, offshore, and heavy industrial sectors, where the combination of strength, corrosion resistance, and self-lubrication provides significant operational advantages over traditional steel solutions.

The choice between Aluminum Bronze Self-Lubricating Bushings and steel bushings hinges on specific application parameters. Steel bushings offer high load capacity where continuous lubrication is feasible. However, Aluminum Bronze Self-Lubricating Bushings provide a robust solution for challenging environments requiring corrosion resistance, reduced maintenance, reliable operation under marginal lubrication, and resistance to seizure. Engineers must carefully evaluate factors like operating environment (corrosive, dirty, submerged), load/speed conditions, temperature, accessibility for maintenance, and total lifecycle cost to determine the optimal bushing technology. For harsh conditions and maintenance-sensitive applications, Aluminum Bronze Self-Lubricating Bushings present a compelling, high-reliability alternative.

English

English 日本語

日本語 русский

русский Deutsch

Deutsch