How Does Copper Alloy Casting Compare to Other Processes?

Selecting the optimal manufacturing process for metal components is critical for performance, cost, and longevity. Copper alloy casting is a prominent method, but understanding how it contrasts with other common processes like forging, machining from billet, and fabrication is essential for engineers and designers.

1. Process Characteristics & Complexity:

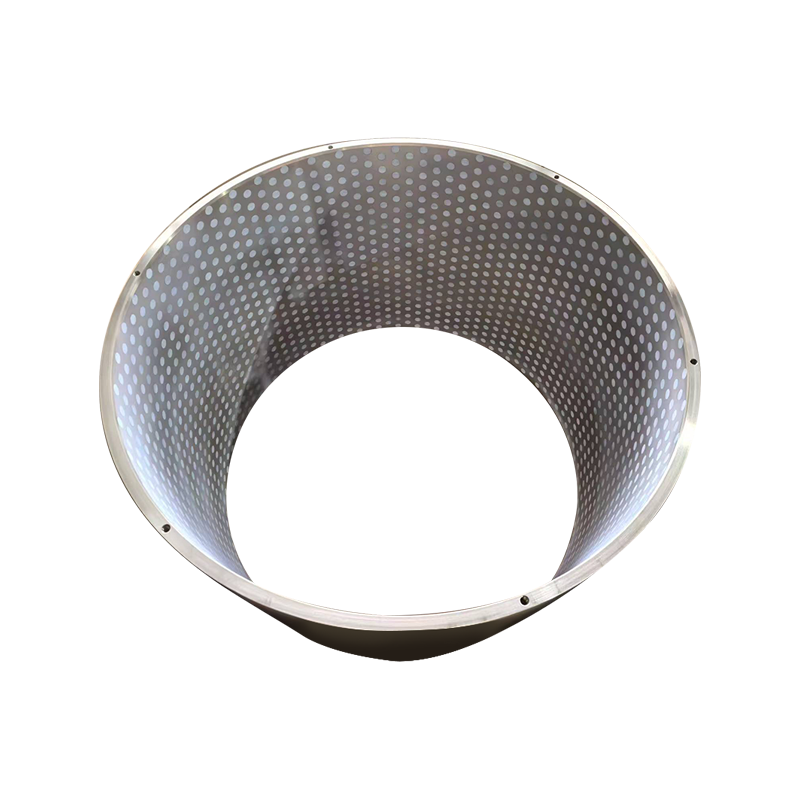

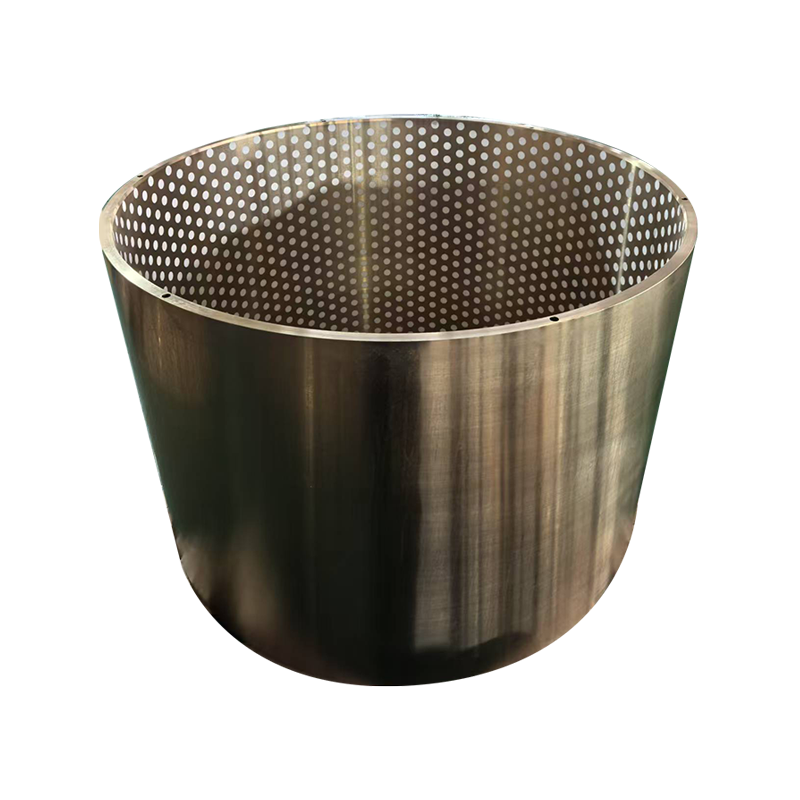

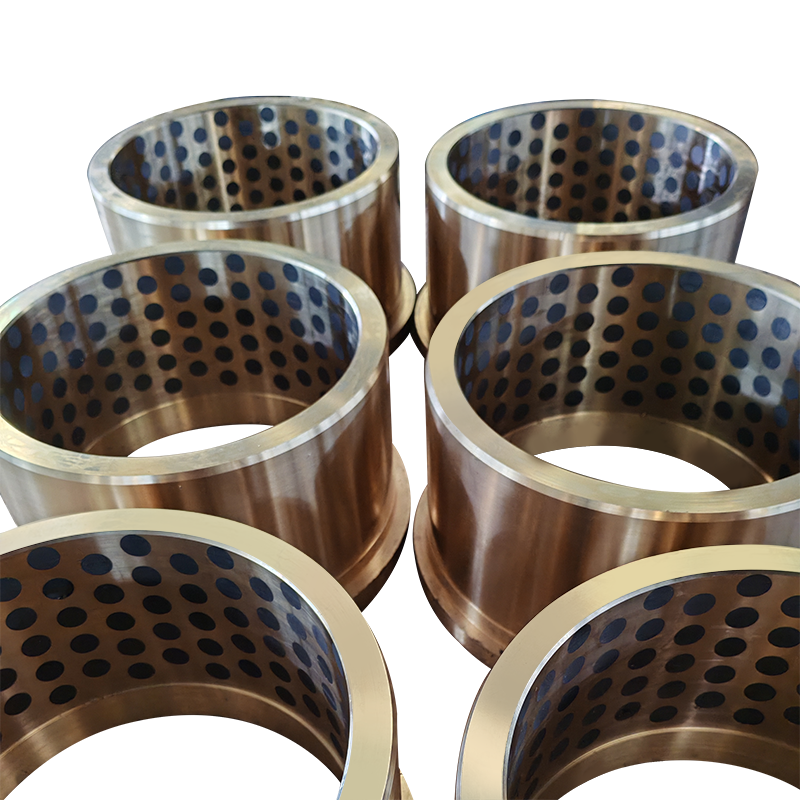

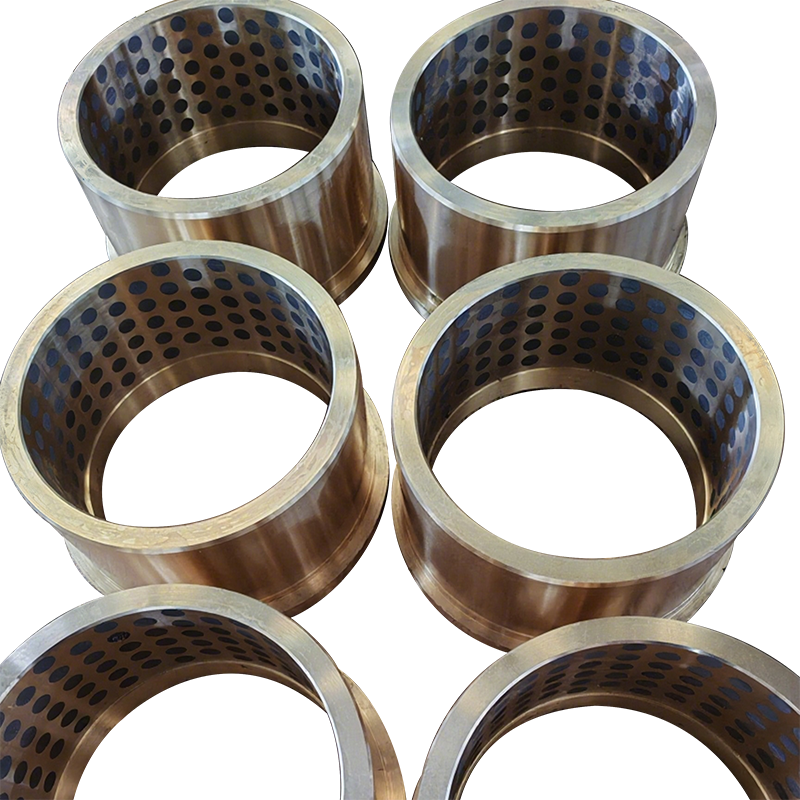

Copper Alloy Casting: Involves pouring molten copper alloys (like bronze, brass, nickel-aluminum bronze) into a mold cavity. It excels at producing complex, near-net-shape geometries – including intricate internal passages, thin walls, and integrated features – that would be extremely difficult or impossible with other methods. Processes include sand casting (versatile, lower tooling cost), investment casting (high precision, fine surface finish), die casting (high volume, excellent dimensional repeatability), and centrifugal casting (ideal for cylindrical parts like bushings).

Forging: Shapes solid metal using localized compressive forces (hammers, presses). Best suited for simpler, high-strength shapes requiring directional grain flow (e.g., crankshafts). Complex geometries are limited.

Machining (from Billet/Bar): Involves removing material from a solid block (billet) or bar stock using cutting tools (CNC milling, turning). Highly precise but generates significant waste (chips), especially for complex parts. Material cost can be high for large components.

Fabrication/Welding: Joins pre-formed components (plate, sheet, tube) via welding, brazing, or mechanical fastening. Suitable for large, simple structures but introduces potential weak points at joints and heat-affected zones, which can be detrimental for corrosion resistance.

2. Material Properties & Performance:

Copper Alloy Casting: Achieves the inherent properties of the chosen copper alloy (e.g., excellent thermal & electrical conductivity, superior corrosion resistance – especially against seawater and chemicals, good machinability, inherent lubricity, non-sparking properties). Properties are generally isotropic. Heat treatment is often used to optimize strength, hardness, or corrosion resistance. Pressure tightness can be excellent with proper foundry practice.

Forging: Enhances strength and toughness through grain refinement and directional alignment. However, it typically uses wrought alloys, which may offer slightly different property balances than castable copper alloys (e.g., potentially lower as-cast corrosion resistance in some environments).

Machining: Retains the properties of the wrought billet/bar stock. While strong, achieving the complex shapes possible via casting often requires extensive machining, increasing cost and potentially compromising integrity if thin sections are needed.

Fabrication: Properties depend heavily on the base materials and the joining process. Welding heat can degrade corrosion resistance in the heat-affected zone (HAZ) of many copper alloys, creating vulnerabilities. Achieving pressure tightness or complex internal geometries is challenging.

3. Economic & Production Factors:

Copper Alloy Casting: Tooling costs vary (high for die casting, lower for sand). Per-unit cost is highly favorable for medium to high volumes and complex parts due to minimal waste and reduced secondary operations. Prototyping can be done (e.g., 3D printed sand molds). Lead times for tooling can be significant.

Forging: High tooling/die costs, justified mainly for very high-volume production of simpler shapes. Material utilization is generally good.

Machining: Low initial tooling cost (programming, fixtures), but high per-unit cost for complex parts due to material waste and long machining times. Ideal for prototypes and very low volumes or extremely high-precision simple parts.

Fabrication: Low initial setup cost for simple structures. Labor-intensive for complex shapes. Costs rise significantly with complexity and volume. Material utilization can be variable.

4. Application Suitability:

Copper Alloy Casting is often the preferred choice when the application demands:

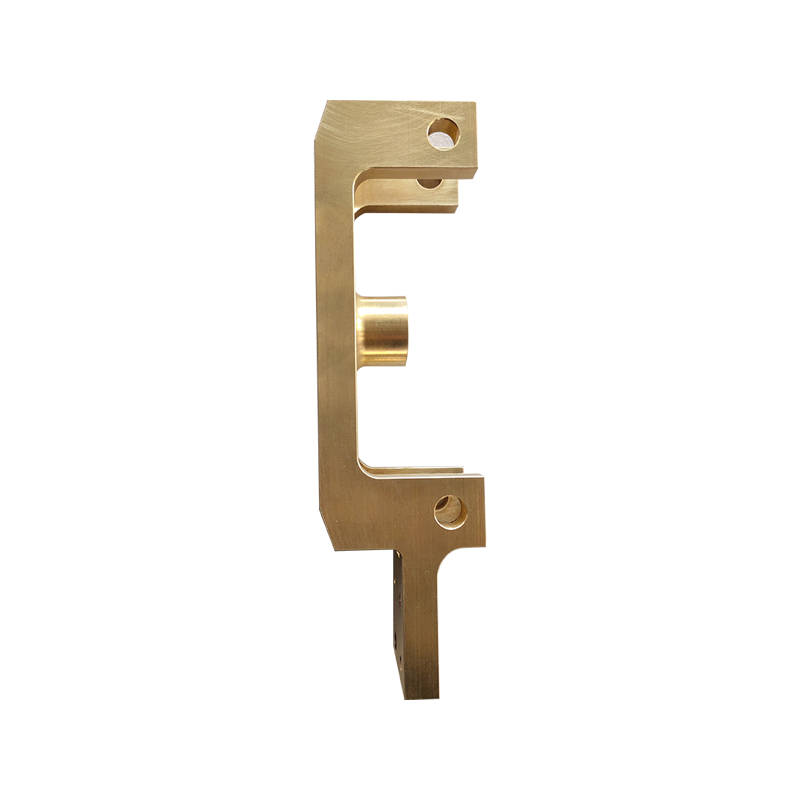

Complex geometries (impellers, valve bodies, pump housings, gears).

Superior corrosion resistance (marine propellers, seawater valves, pump components).

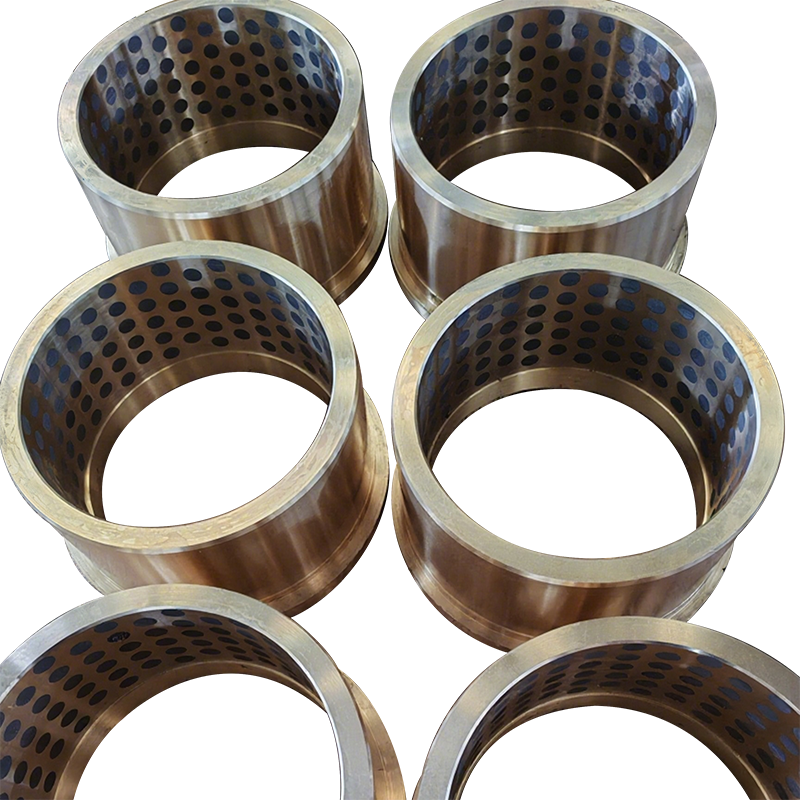

Excellent bearing/bushing properties and wear resistance.

Good machinability post-casting.

Thermal/electrical conductivity needs.

Non-sparking requirements (mining equipment).

This makes it indispensable in sectors like marine propulsion and sealing systems, offshore drilling platforms, ship lock lifting systems, mining equipment, and demanding industrial valves and pumps – areas where companies like Yangzhou Yifeng Copper Products Co., Ltd. specialize in producing high-end cast copper alloy components.

Forging excels for high-strength, fatigue-critical parts with simpler shapes (shafts, connecting rods).

Machining is optimal for prototypes, low volumes, or parts requiring extreme precision from simpler wrought stock.

Fabrication is suitable for large, low-complexity structures, frames, or enclosures where joining is practical.

Copper alloy casting offers a unique combination of design freedom, material performance (especially corrosion resistance), and economic efficiency for medium-to-high volume production of complex components. While forging provides superior strength in simpler shapes, machining offers precision for simpler geometries at lower volumes, and fabrication suits large structures, copper alloy casting stands out when intricate design, inherent corrosion resistance, specific wear properties, and overall cost-effectiveness for complex parts are paramount. The choice ultimately depends on the specific requirements of the component, including geometry, performance needs, volume, and budget. For critical applications in harsh environments demanding complex copper alloy parts, casting frequently presents the most technically and economically viable solution.

English

English 日本語

日本語 русский

русский Deutsch

Deutsch