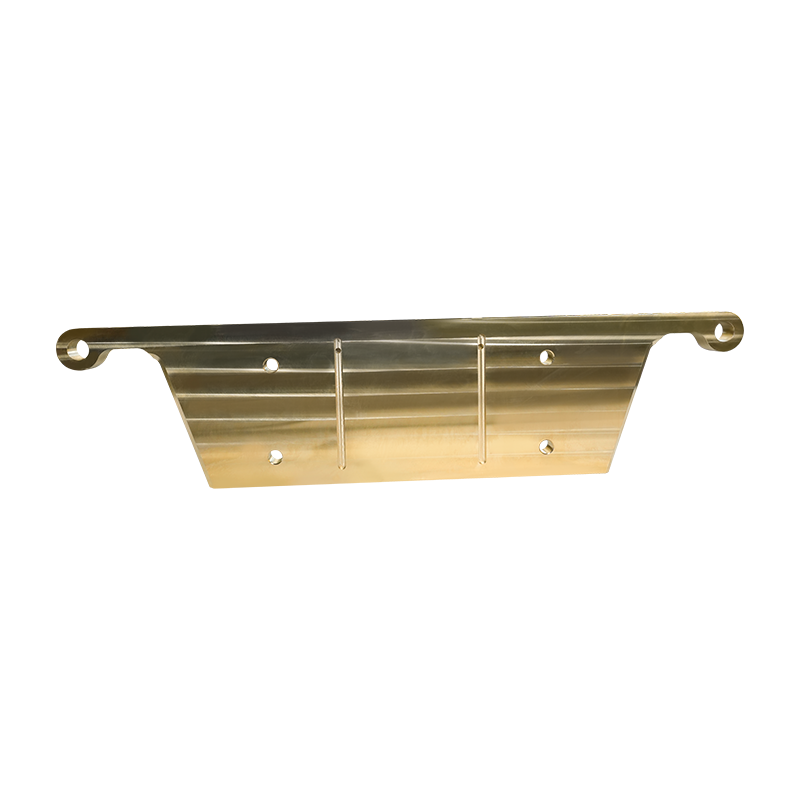

Why Choose Brass Plate for Construction Machinery Parts?

The selection of materials for construction machinery parts demands careful consideration of performance, durability, and cost-effectiveness. Among various options, brass plate continues to hold significant relevance in specific critical applications.

Key Advantages Driving Selection:

Exceptional Corrosion Resistance: Brass plate offers superior resistance to corrosion, particularly in environments exposed to water, humidity, chemicals, and saline conditions common on construction sites. This significantly reduces component degradation, rust formation, and premature failure, extending service life and minimizing unplanned downtime.

Superior Machinability: Brass plate is renowned for its excellent machinability. It allows for high-speed machining with good surface finishes and dimensional accuracy, reducing manufacturing time and tool wear compared to many steels. This efficiency translates into cost savings during production and facilitates the creation of complex geometries often required in machinery parts.

High Strength and Fatigue Resistance: While not matching the ultimate tensile strength of high-grade steels, brass plate provides a favorable combination of strength, toughness, and excellent fatigue resistance. This makes it suitable for components subjected to repeated stress cycles, vibrations, and impacts, such as bushings, wear plates, valve bodies, and thrust washers.

Excellent Bearing and Wear Properties: Brass plate inherently possesses good bearing characteristics and wear resistance. Its relatively low friction coefficient against steel makes it ideal for applications involving sliding contact or as a bearing surface, reducing galling and seizing. This is crucial for pivot points, guides, and other moving interfaces within heavy machinery.

Non-Sparking Characteristic: In potentially explosive environments, such as those involving flammable gases or dust (e.g., on mining sites or certain demolition projects), the non-sparking nature of brass plate is a critical safety advantage over ferrous materials. This property helps mitigate the risk of ignition during component operation or impact.

Good Thermal and Electrical Conductivity: For components requiring efficient heat dissipation or specific electrical properties, brass plate provides significantly better thermal and electrical conductivity than steel. This can be relevant for heat sinks, electrical grounding components, or parts adjacent to heat sources.

Recyclability: Brass is highly recyclable without loss of properties, aligning with growing industry emphasis on sustainable material practices and end-of-life component management.

Common Construction Machinery Applications:

Bushings and Bearings: Especially in pivot joints, linkages, and undercarriage components where corrosion resistance and low friction are paramount.

Wear Plates and Liners: Protecting structural components from abrasion in high-wear areas.

Hydraulic Valve Components: Valve bodies, seats, and spools benefiting from machinability, corrosion resistance, and pressure integrity.

Thrust Washers and Gears: Handling axial loads and providing wear surfaces.

Sealing Components and Glands: Particularly in hydraulic and fluid systems exposed to harsh conditions.

Electrical Contacts and Grounding Components: Utilizing its conductivity.

Fasteners and Fittings: Used in corrosive environments where non-sparking is required.

Sourcing Considerations:

Optimal performance requires sourcing high-quality brass plate. Reputable manufacturers, such as Yangzhou Yifeng Copper Products Co., Ltd., specialize in producing high-end copper alloy products, including brass plate tailored for demanding industrial environments. Such suppliers possess the metallurgical expertise and quality control processes necessary to ensure consistent material properties – including precise alloy composition, mechanical strength, dimensional tolerances, and surface quality – essential for critical construction machinery parts. Industries like mining equipment, marine applications, and offshore platforms, where brass plate is frequently specified, rely on suppliers capable of meeting stringent performance and reliability standards.

While advanced steels and polymers offer solutions for many applications, brass plate retains a vital niche in construction machinery manufacturing. Its unique combination of corrosion resistance, machinability, favorable bearing properties, strength, and non-sparking safety feature makes it an indispensable material for specific, often critical, components. The choice of brass plate is fundamentally driven by engineering requirements focused on long-term reliability, performance under harsh operating conditions, safety, and overall cost-effectiveness throughout the component's lifecycle. Selecting high-grade brass plate from experienced suppliers remains a strategic decision for enhancing the durability and functionality of construction equipment.

English

English 日本語

日本語 русский

русский Deutsch

Deutsch