What industrial scenarios is Tin Bronze Bushing suitable for?

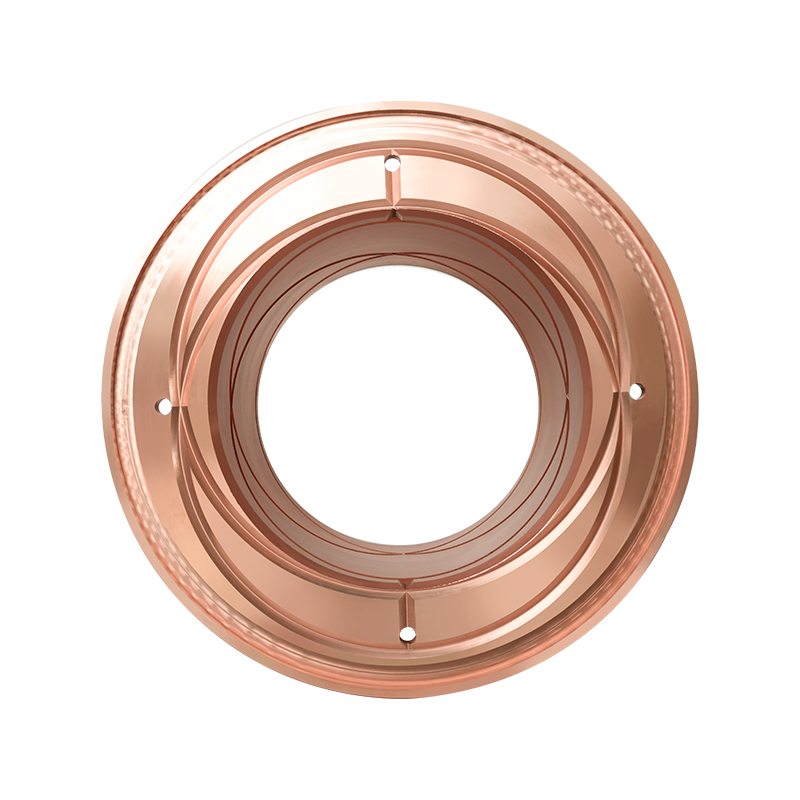

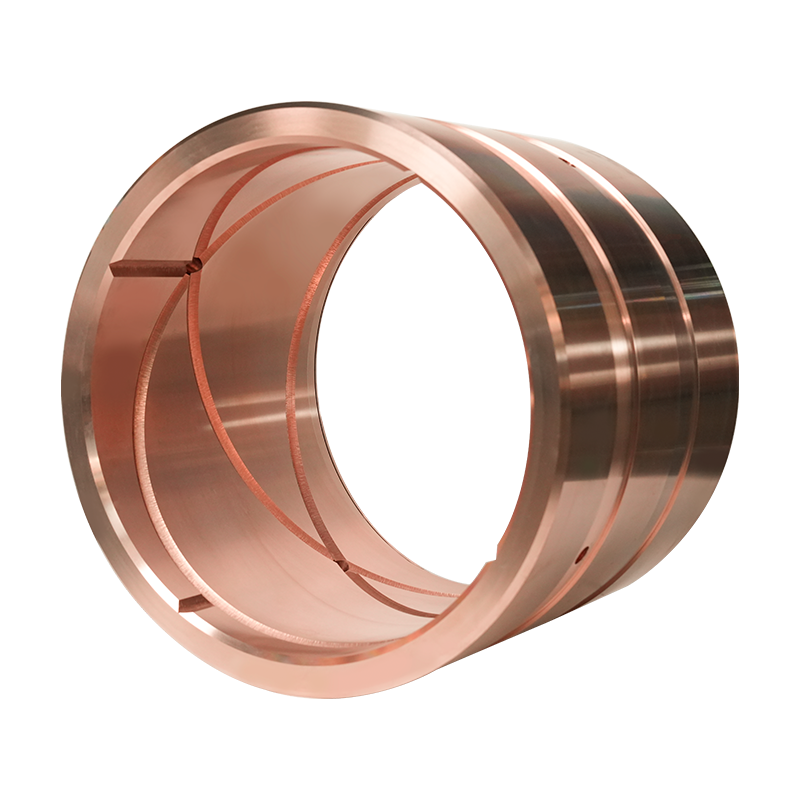

Tin Bronze Bushings represent a critical class of engineered components, valued across demanding industrial sectors for their unique combination of properties. Composed primarily of copper alloyed with tin (typically 3-14%) and often incorporating elements like phosphorus, zinc, or lead, these bushings deliver exceptional performance where reliability under harsh conditions is paramount.

Core Advantages Driving Application Selection:

High Load Capacity: Excellent resistance to deformation under heavy static and dynamic loads.

Wear Resistance: Superior performance against friction and abrasion, extending component life.

Corrosion Resistance: Good resistance to various corrosive environments, including moisture, seawater, and many chemicals.

Conformability & Embeddability: Ability to accommodate minor shaft misalignment and embed abrasive particles, reducing shaft wear.

Low Friction & Good Lubricity: Maintains effective sliding surfaces, especially when lubricated, though some grades offer inherent lubricity.

Machinability: Relatively easy to manufacture into precise dimensions and complex shapes.

Primary Industrial Scenarios for Tin Bronze Bushing Deployment:

Mining & Mineral Processing Equipment: The abrasive nature of ores, dust, and slurries demands components with high wear resistance. Tin Bronze Bushings are extensively used in crushers, grinding mills, conveyors, shaker screens, and excavator pivot points. Their ability to withstand heavy impact loads and embed particulate matter protects more expensive shafts and housings. Companies like Yangzhou Yifeng Copper Products Co., Ltd. often supply these components for critical mining machinery.

Marine Propulsion & Systems: Constant exposure to saltwater corrosion, high loads from propeller shafts, and the need for reliable sealing make marine environments exceptionally challenging. Tin Bronze Bushings are vital in:

Sterntube Bearings: Supporting the propeller shaft.

Rudder Bearings: Pivoting points for rudder stocks.

Pump and Valve Stems: Ensuring smooth operation in seawater cooling and ballast systems.

Sealing System Components: Where low friction and corrosion resistance are critical adjacent to seals.

Metallurgical Machinery: High temperatures, heavy loads, and potential contamination characterize steel mills, foundries, and metal processing plants. Tin Bronze Bushings perform reliably in:

Rolling Mill Stands: Guide boxes and backup roll chocks.

Continuous Casting Equipment: Support rolls and oscillation mechanisms.

Furnace Doors & Charging Equipment: Handling thermal cycling and mechanical stress.

Oil & Gas Exploration & Production (Onshore & Offshore): Equipment in this sector faces extreme pressures, corrosive fluids (oil, gas, drilling mud, seawater), and often remote locations demanding maximum uptime. Tin Bronze Bushings are found in:

Drill String Components: Subs, stabilizers (where permitted/alloy suitable).

Pump & Compressor Bearings: Handling high loads in fluid transfer.

Valve & Actuator Trunnions: Providing smooth pivoting motion under load.

Offshore Platform Machinery: Cranes, winches, tensioners, and heave compensation systems exposed to the marine environment.

Heavy Machinery & General Industrial Applications:

Construction Equipment: Excavators, cranes, bulldozers (pins, linkages, pivot points).

Hydraulic Cylinders: Wear bands and clevis mounts.

Power Generation: Turbine governor linkages, auxiliary equipment bearings.

Water Control Infrastructure: Critical in components like ship lock lifting systems and large sluice gate hinges, where corrosion resistance (fresh or saltwater) and load capacity are essential. Manufacturers specializing in sectors like marine and infrastructure, such as Yangzhou Yifeng Copper Products Co., Ltd., frequently provide Tin Bronze Bushings for these demanding applications.

Selection Considerations:

While Tin Bronze Bushings excel in these areas, proper selection is crucial. Factors include:

Specific Alloy Composition: Different grades (e.g., SAE 841, C93200, C93700) offer variations in strength, hardness, corrosion resistance, and lubricity.

Load Type & Magnitude: Steady vs. shock loading.

Operating Speed: Low to moderate speeds are typical strongholds.

Lubrication Regime: Availability and type of lubrication significantly impact performance and lifespan.

Environmental Factors: Temperature extremes, chemical exposure, presence of abrasives.

Shaft Material & Hardness: Compatibility is vital to minimize adhesive wear.

The Tin Bronze Bushing remains an indispensable solution for numerous heavy-duty industrial applications. Its proven performance under high loads, resistance to wear and corrosion (particularly in marine settings), and forgiving nature regarding misalignment and contamination solidify its role in sectors ranging from mining and marine propulsion to metallurgy, energy, and major infrastructure. Understanding the specific operating environment and selecting the appropriate tin bronze alloy grade are fundamental steps in leveraging the full benefits of this durable and reliable bearing material.

English

English 日本語

日本語 русский

русский Deutsch

Deutsch