How to Select the Right Copper Alloy Plate Thickness?

Choosing the correct thickness for a copper alloy plate is a critical engineering decision impacting performance, longevity, safety, and cost-effectiveness.

1. Define the Primary Functional Requirements:

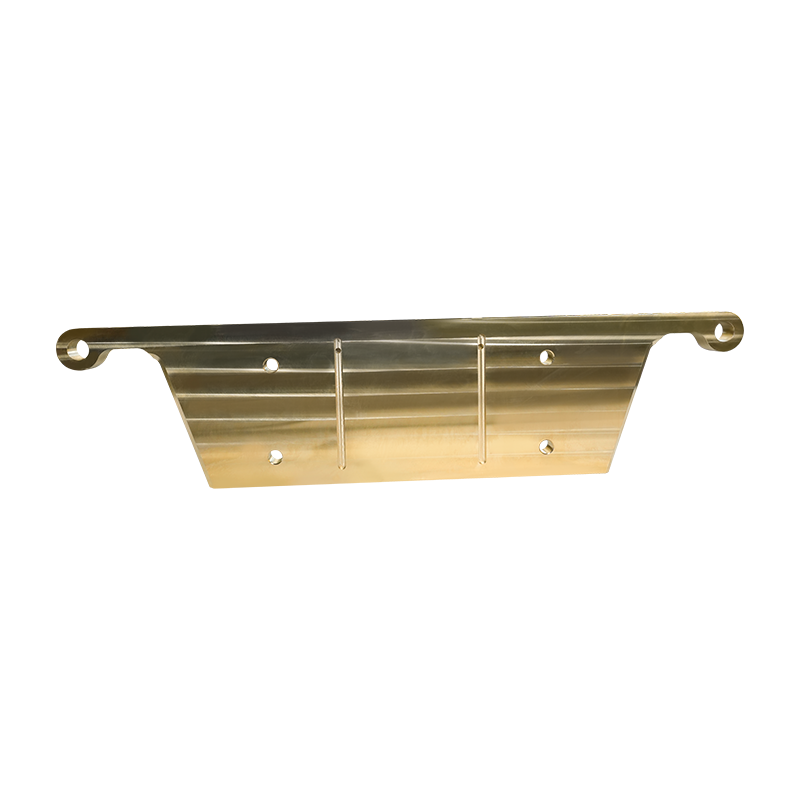

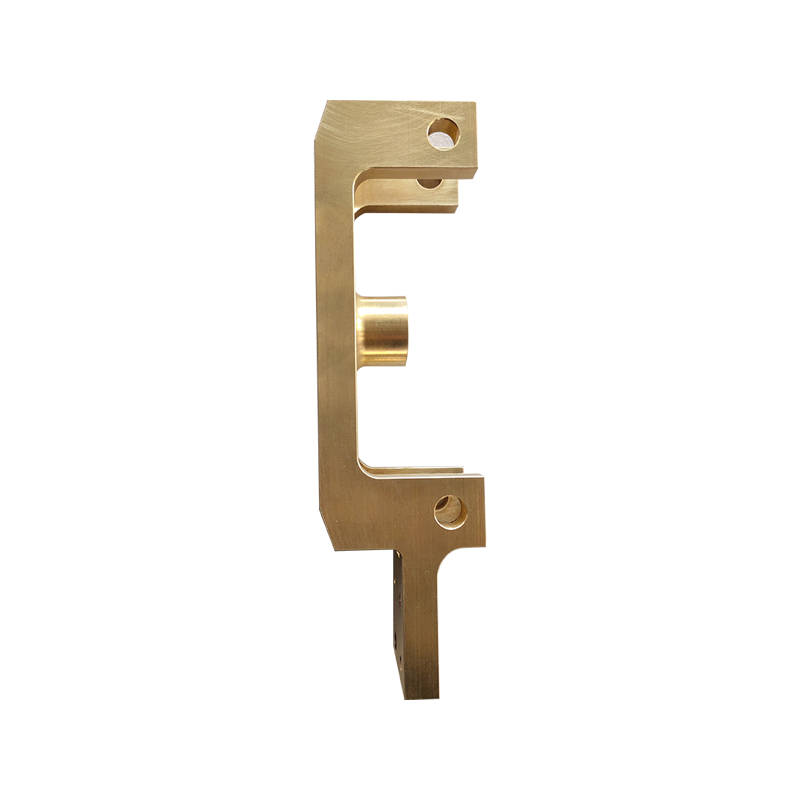

* Mechanical Load: Calculate anticipated static and dynamic loads (tensile, compressive, shear, impact). Finite Element Analysis (FEA) is often essential. Thickness directly influences load-bearing capacity and resistance to deformation (bending, buckling). Higher loads necessitate thicker plates or higher-strength alloys.

* Wear Resistance: Applications involving abrasion or erosion (e.g., mining equipment chutes, crusher liners, ship lock components) require sufficient thickness to provide an adequate wear allowance over the component's design life.

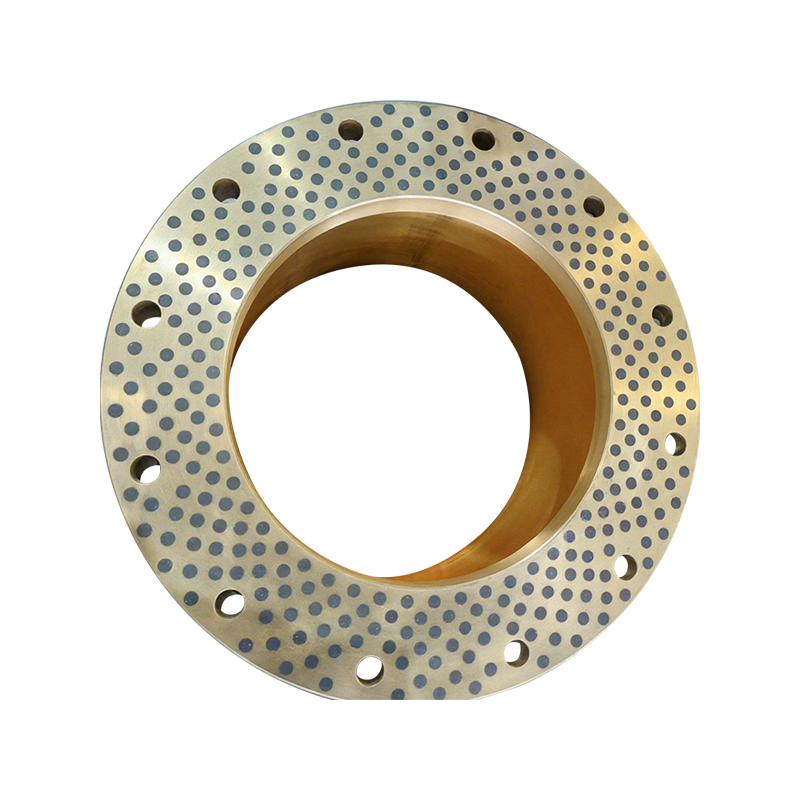

* Pressure & Vacuum: For vessels, sealing systems (like marine propulsion shaft seals), or components under significant internal/external pressure (oil & gas equipment), thickness is paramount for structural integrity and safety, often governed by codes like ASME BPVC. Vacuum chambers require resistance to buckling.

2. Evaluate the Operating Environment:

* Corrosion/Erosion: Assess the severity and type of corrosion (general, pitting, galvanic, stress corrosion cracking) or erosion (solid particle, liquid impingement). Harsh environments (seawater in marine propulsion, acidic slurries in mining, chemical exposure offshore) demand greater thickness to incorporate a corrosion allowance – extra material sacrificed over time. Alloy selection (e.g., aluminum bronze, nickel-aluminum bronze, cupronickel) is intrinsically linked to this factor.

* Temperature: Consider operational temperature ranges. Thermal cycling can induce fatigue; elevated temperatures may reduce strength, potentially requiring increased thickness. Thermal conductivity requirements also play a role in thermal management applications.

3. Consider Fabrication and Service Life Factors:

* Manufacturing Processes: Machining, forming (bending, rolling), welding, or cladding processes influence thickness selection. Sufficient initial thickness is needed to achieve final dimensions after machining. Formability may limit how thick a plate can be bent for specific radii. Welding procedures require minimum thicknesses.

* Component Life Expectancy: Design for the required service life. A critical component on an offshore drilling platform or within a ship lock lifting system necessitates a more conservative thickness selection with larger safety factors and corrosion allowances than a less critical part.

* Weight and Space Constraints: While thicker plates offer strength, they increase weight and occupy more space. Applications like marine propulsion or mobile equipment require optimization to meet weight targets without compromising safety or performance. High-strength alloys can sometimes allow for thinner sections.

4. Cost Optimization and Availability:

* Material Cost: Copper Alloy Plate represents a significant material cost. Specifying excessive thickness wastes material. Precise calculation based on actual requirements is crucial for cost control.

* Fabrication Cost: Thicker plates may incur higher machining, forming, or welding costs. Balance material cost against processing costs.

* Standard Sizes: Check standard mill plate thickness availability (e.g., metric or imperial gauges). Choosing a non-standard thickness can lead to long lead times and significantly higher costs. Reputable suppliers like Yangzhou Yifeng Copper Products Co., Ltd., specializing in high-end copper alloys for sectors including mining equipment, marine systems, oil and gas, and offshore platforms, typically stock or can efficiently produce common thicknesses meeting international standards.

The Selection Process: A Practical Approach

Quantify Requirements: Gather precise data on loads, pressures, temperatures, corrosion factors, wear mechanisms, design life, and dimensional constraints.

Select Alloy: Choose the copper alloy (e.g., C63000 Aluminum Bronze, C70600 Cupronickel, C17200 Beryllium Copper) best suited to the environment and mechanical needs. Alloy properties dictate the necessary thickness for a given load.

Perform Calculations: Utilize engineering principles (beam theory, pressure vessel formulas), material property data (yield strength, fatigue strength, modulus of elasticity), and applicable design codes to calculate the minimum required thickness based on static and dynamic stresses.

Add Allowances: Add calculated corrosion/wear allowances based on environment severity and design life. Apply appropriate safety factors as mandated by standards or project specifications.

Consider Fabrication: Factor in material removal during machining or potential thinning during forming. Consult fabrication experts if processes are complex.

Check Standards & Availability: Ensure the calculated thickness (including allowances) aligns with standard mill plate sizes. Consult suppliers regarding availability and potential cost premiums for non-standard sizes.

Review and Iterate: Evaluate the proposed thickness against weight, space, and cost targets. Consider if a higher-strength alloy could enable a thinner, more optimal section. Refine as necessary.

Selecting the right Copper Alloy Plate thickness is a fundamental engineering task requiring a systematic analysis of functional demands, environmental conditions, fabrication realities, and economic factors. There is no universal answer; the optimal thickness is application-specific. By rigorously evaluating mechanical loads, corrosion potential, thermal effects, wear, manufacturability, and cost, engineers can specify the most technically sound and economically viable Copper Alloy Plate thickness, ensuring reliable performance and longevity in critical applications across diverse industries. Manufacturers with expertise in supplying these materials for demanding environments, such as those serving mining, marine propulsion, oil and gas, and heavy machinery sectors, are valuable partners in confirming the suitability and availability of specific alloys and thicknesses.

English

English 日本語

日本語 русский

русский Deutsch

Deutsch