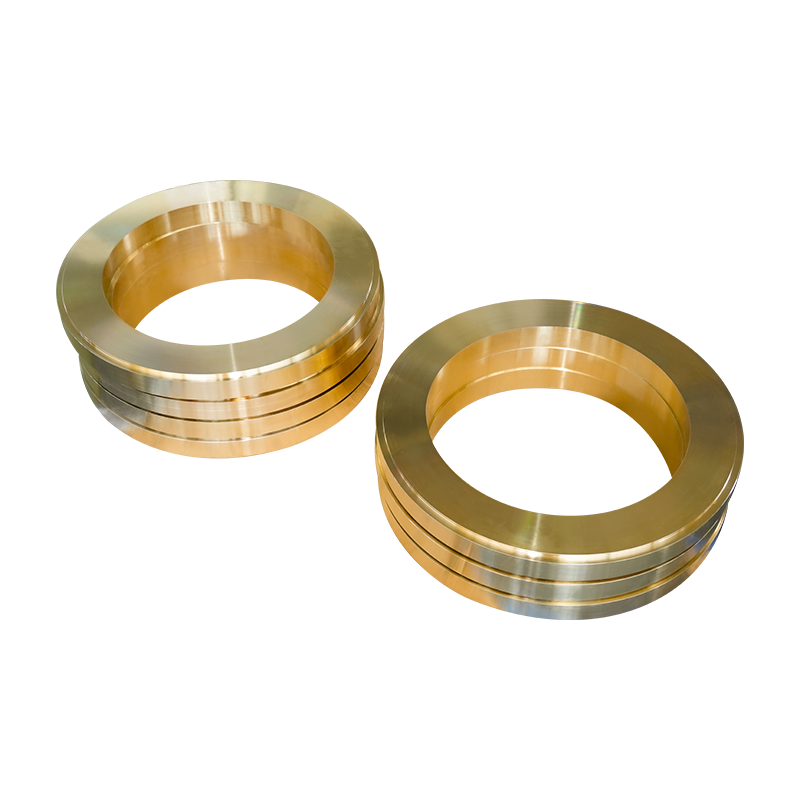

How do Brass Bushings reduce friction?

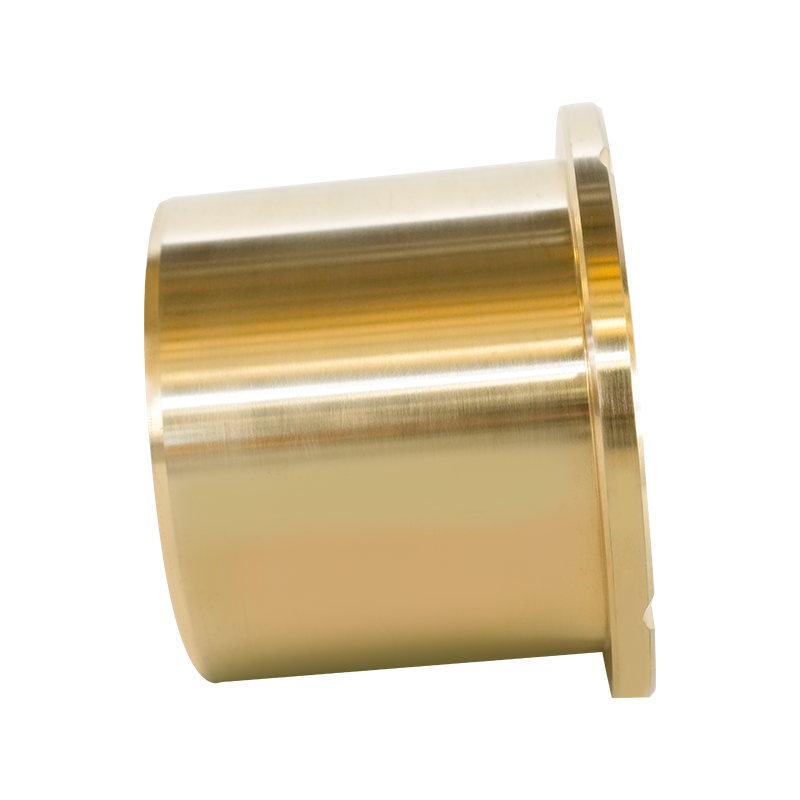

Friction is a persistent challenge in rotating and sliding machinery components, leading to energy loss, wear, and premature failure. Brass bushings, widely employed across demanding industrial sectors, provide an effective and reliable solution for managing friction. Understanding the mechanisms behind their friction-reducing capabilities is crucial for selecting appropriate components for specific applications.

1. Material Composition and Inherent Lubricity:

Brass, an alloy primarily of copper and zinc, possesses inherent properties beneficial for friction reduction. Its relatively soft nature compared to hardened steel shafts allows microscopic asperities on the shaft surface to embed slightly into the bushing material. This embedding action prevents the harder shaft asperities from ploughing through the bushing material, significantly reducing adhesive wear and the associated friction forces. While softer than the shaft, brass maintains sufficient strength and load-carrying capacity for many applications.

2. Conformability and Embeddability:

Beyond inherent lubricity, brass exhibits excellent conformability. It can adapt to minor misalignments or deflections in the shaft, ensuring a more uniform distribution of load and contact pressure. This adaptability prevents localized high-pressure points that generate excessive friction and wear. Furthermore, brass bushings effectively embed small, hard contaminants (like dust or grit particles) that might enter the interface. By trapping these particles within the bushing material, they are prevented from scoring or abrading the more critical (and expensive) shaft surface, thereby maintaining lower friction levels and protecting the shaft.

3. Compatibility with Lubricants:

Brass bushings work exceptionally well in conjunction with lubricants, significantly enhancing their friction-reducing capabilities:

Oil Retention: The porous microstructure of certain brass alloys allows them to absorb and retain oil. This creates a reservoir effect, continuously supplying lubricant to the sliding interface even during intermittent operation, helping to maintain a lubricating film.

Oil Distribution: The surface properties of brass facilitate the spreading and maintenance of an oil film across the contact area. This film separates the shaft and bushing surfaces, drastically reducing metal-to-metal contact and shifting friction towards the much lower fluid friction regime (hydrodynamic lubrication).

Boundary Lubrication Performance: Even in conditions where a full hydrodynamic film cannot be sustained (e.g., startup, shutdown, low speed, high load), brass maintains relatively low friction under boundary lubrication. The alloy interacts effectively with lubricant additives designed to protect surfaces under these harsh conditions.

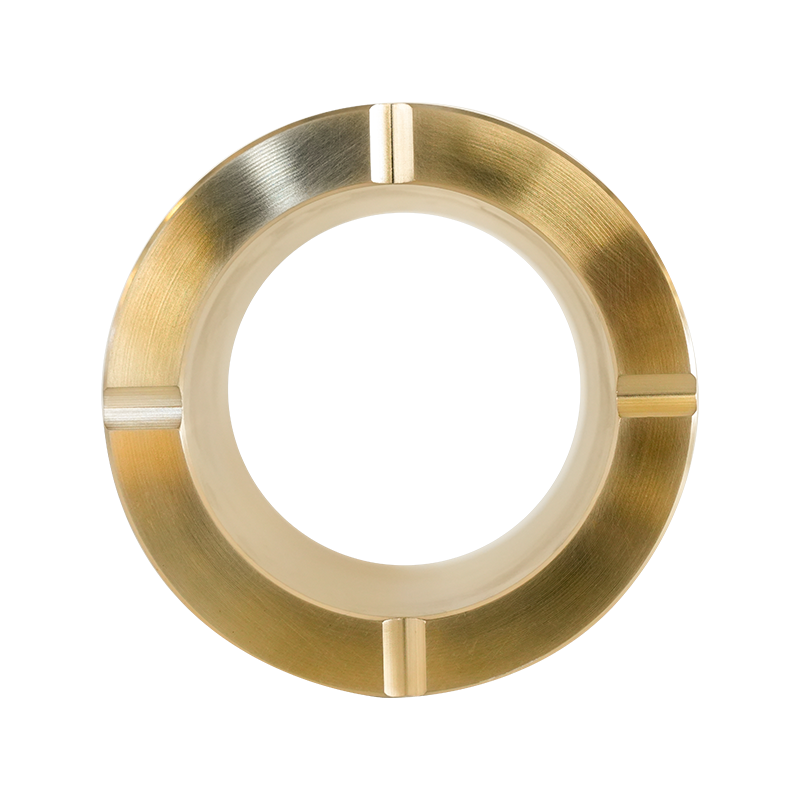

4. Incorporation of Solid Lubricants (Common Enhancement):

Many brass bushings are enhanced by incorporating solid lubricants directly into their structure:

Graphite Plugs: Bushings often feature machined holes filled with graphite plugs. As the bushing wears, graphite is continuously released onto the sliding surface. Graphite has an extremely low coefficient of friction and provides lubrication, especially in dry or marginally lubricated conditions, or at high temperatures where oils might degrade.

Oil-Impregnated Sintered Bronze (Often Brass-Based): While technically bronze (copper-tin), sintered bushings frequently utilize brass alloys. The sintering process creates a porous matrix that can be vacuum-impregnated with oil. This provides a long-lasting, self-lubricating effect ideal for applications where re-lubrication is difficult or impossible.

5. Corrosion Resistance (Indirect Contribution):

While not a direct friction-reduction mechanism, the good corrosion resistance of many brass alloys (particularly those with additional elements like aluminum or manganese) prevents the formation of rust and corrosive products on the sliding surface. Such products typically act as abrasives, drastically increasing friction and wear. Maintaining a clean interface is thus indirectly vital for sustained low friction.

Applications Leveraging Friction Reduction:

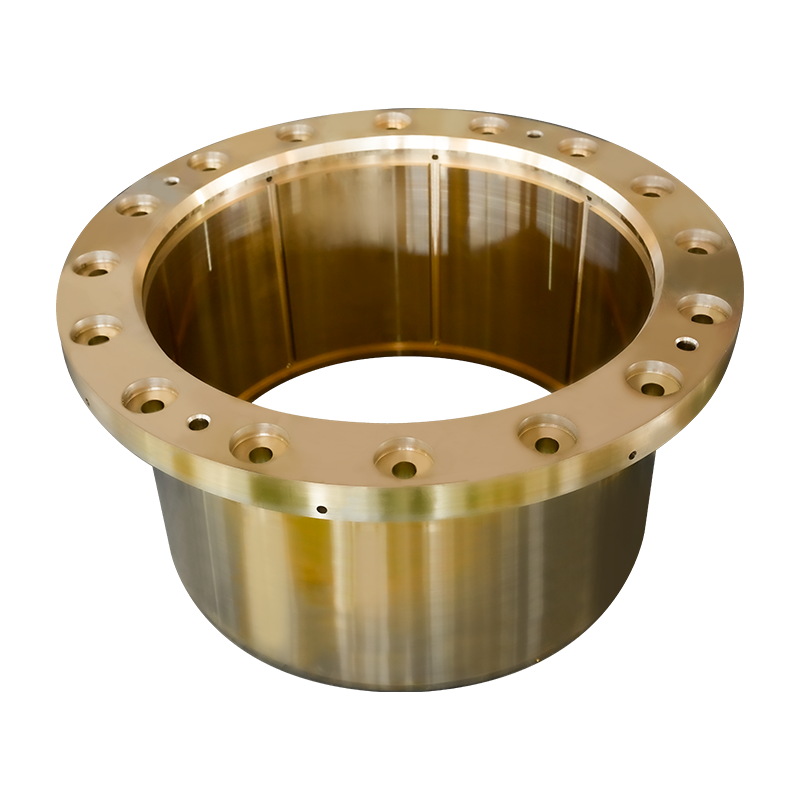

The friction-reducing properties of brass bushings make them indispensable in numerous heavy-duty applications, such as:

Mining Equipment: Conveyor systems, crushers, screens (handling abrasive dust, high loads, vibration).

Marine Propulsion and Sealing Systems: Rudder stocks, propeller shafts, pump components (exposure to water, corrosion challenges).

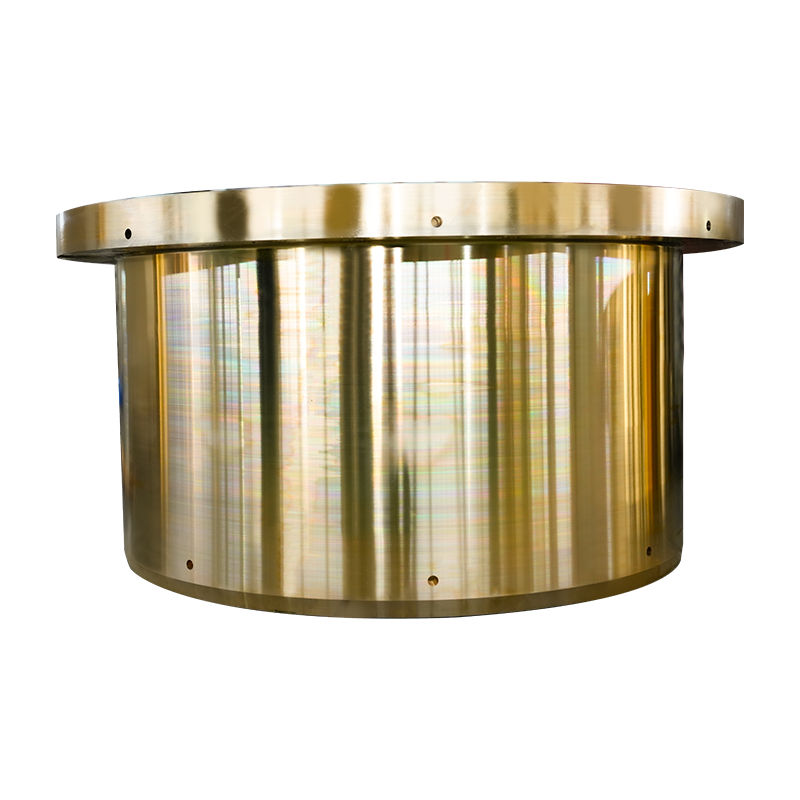

Metallurgical Machinery: Rolling mills, casting equipment (high temperatures, heavy loads).

Oil and Gas Equipment / Offshore Drilling Platforms: Valves, draw-works, mud pumps (harsh environments, critical reliability).

Ship Lock Lifting Systems: Gears, hinges, gate mechanisms (intermittent operation, high static loads, exposure to elements).

Specialized manufacturers, such as Yangzhou Yifeng Copper Products Co., Ltd., focus on producing high-grade brass bushings tailored to meet the stringent friction, wear, load, and environmental demands of these critical industrial sectors.

Brass bushings reduce friction through a combination of their inherent material properties (softness, embeddability, conformability), excellent compatibility with and retention of lubricating oils, and the frequent incorporation of solid lubricants like graphite. Their ability to embed contaminants, perform under boundary lubrication, and resist corrosion further contributes to maintaining low friction coefficients and protecting mating shafts. These characteristics make brass bushings a fundamental and reliable choice for managing friction in a vast array of rotating and sliding machinery components across diverse and demanding industries. Proper selection, installation, and maintenance (including lubrication where applicable) are essential to maximize their friction-reducing performance and service life.

English

English 日本語

日本語 русский

русский Deutsch

Deutsch