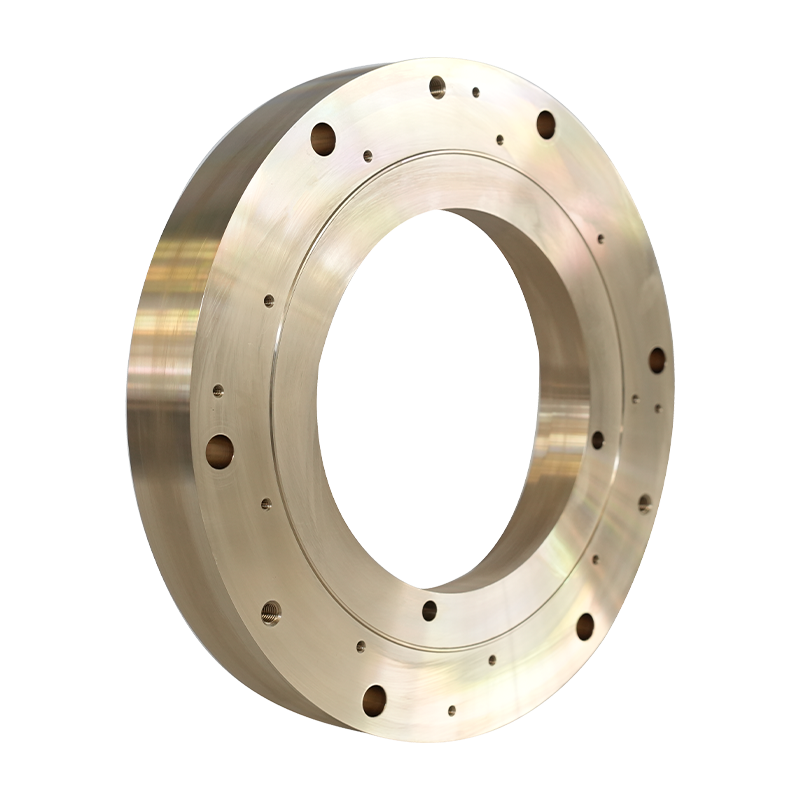

How Does Marine Copper Alloy Sealing Ring Resist Corrosion?

Marine environments present extreme challenges for sealing components, demanding exceptional resistance to corrosion. Seawater's high salinity, dissolved oxygen, and biological activity create a potent electrolyte capable of rapidly degrading many metals. Within this demanding context, Marine Copper Alloy Sealing Rings have established themselves as a critical solution, particularly in propulsion systems, pumps, valves, and stern tube seals.

The core resistance stems from the inherent properties of copper and the strategic alloying elements employed:

Formation of Protective Oxide Films: Copper naturally forms a thin, adherent oxide layer (primarily cuprous oxide, Cu₂O) on its surface upon exposure to oxygen, even in aqueous environments. This passive film acts as a barrier, significantly slowing down the rate of further oxidation and metal dissolution. While pure copper offers some protection, marine alloys enhance this significantly.

Strategic Alloying for Enhanced Passivity: Marine copper alloys, such as aluminum bronzes (e.g., C95400, C95500) and nickel-aluminum bronzes (e.g., C95800, C63000), incorporate elements like aluminum, nickel, iron, and manganese.

Aluminum: Forms a highly protective, dense, and adherent aluminum oxide (Al₂O₃) layer within the copper oxide matrix. This alumina layer is exceptionally stable in seawater, dramatically improving resistance to pitting, crevice corrosion, and impingement attack. It also enhances resistance to biofouling.

Nickel: Improves the overall stability and protectiveness of the passive film. It enhances resistance to corrosion fatigue, stress corrosion cracking (SCC), and erosion-corrosion, common failure modes in dynamic sealing applications. Nickel also strengthens the alloy matrix.

Iron & Manganese: Primarily contribute to strengthening the alloy microstructure and can enhance the stability of the protective surface film.

Microstructure Control: The corrosion resistance is highly dependent on the alloy's microstructure, achieved through controlled casting, heat treatment (e.g., quenching and tempering), and sometimes wrought processing. Proper heat treatment ensures a homogeneous structure with finely distributed beneficial intermetallic phases (like the tough kappa phase in aluminum bronzes) that support the protective film and resist localized attack. Inappropriate processing can lead to detrimental phases that compromise corrosion resistance.

Galvanic Compatibility: While copper alloys are noble relative to steels, careful selection within the copper alloy family ensures good galvanic compatibility with common mating components like stainless steel shafts or housings, minimizing galvanic corrosion risks. The protective oxide film itself also reduces the driving force for galvanic action. Proper system design and material pairing remain crucial.

Resistance to Specific Attack Modes: Marine copper alloys are specifically chosen for their resistance to:

Dezincification: Brass alloys (copper-zinc) are highly susceptible to selective zinc leaching in seawater. Marine alloys minimize or eliminate zinc content, using aluminum, nickel, and tin instead.

Cavitation Erosion: The tough microstructure and adherent oxide layer provide good resistance to damage caused by collapsing vapor bubbles in high-velocity flows.

Stress Corrosion Cracking (SCC): Properly processed nickel-aluminum bronzes exhibit excellent resistance to SCC in seawater, a critical factor for highly stressed sealing rings.

Manufacturing and Application Influence: The inherent corrosion resistance of the base alloy must be coupled with high-quality manufacturing. Precise machining ensures optimal sealing surfaces, minimizing crevices where localized corrosion can initiate. Surface finish also impacts film formation and adherence. Furthermore, correct installation to avoid excessive stress concentrations and ensuring compatibility with the operating environment (temperature, flow velocity, pH) are vital for realizing the full corrosion resistance potential of the sealing ring.

Manufacturers specializing in these critical components, such as Yangzhou Yifeng Copper Products Co., Ltd., leverage expertise in metallurgy and processing to produce Marine Copper Alloy Sealing Rings. Their focus on high-end copper alloys for demanding sectors like marine propulsion, sealing systems, and offshore platforms underscores the importance of controlled composition, microstructure optimization, and precise manufacturing in achieving the necessary corrosion performance.

The corrosion resistance of Marine Copper Alloy Sealing Rings is not a single attribute but the result of synergistic factors: the formation and stability of protective oxide films (enhanced by aluminum and nickel), a carefully controlled microstructure achieved through proper alloying and processing, and inherent resistance to specific marine corrosion mechanisms like dezincification and SCC. This multifaceted protection, combined with precise manufacturing and correct application, makes these alloys indispensable for reliable, long-lasting sealing in the aggressive marine environment, safeguarding critical equipment and operations.

English

English 日本語

日本語 русский

русский Deutsch

Deutsch