How Does Aluminum Bronze Plate Perform in Seawater Environments?

Seawater presents one of the most aggressive natural environments for metallic components, demanding materials with exceptional corrosion resistance, biofouling resistance, and mechanical integrity. Aluminum Bronze Plate consistently demonstrates superior performance in these challenging conditions, making it a critical material for marine engineering.

Understanding the Seawater Challenge

Seawater's corrosivity stems from high chloride ion concentration, dissolved oxygen, varying pH, microbiological activity (MIC), and potential for erosion/cavitation. Components face pitting, crevice corrosion, galvanic attack, stress corrosion cracking (SCC), and impingement damage. Materials like standard stainless steels often succumb rapidly to localized corrosion.

Aluminum Bronze Plate: Key Performance Attributes

Superior Corrosion Resistance: Aluminum Bronze Plate (typically alloys like C95400, C95500, C95800) forms a robust, self-repairing protective oxide layer, primarily aluminum oxide (Al₂O₃), upon exposure. This adherent film provides excellent resistance to:

General Corrosion: Very low uniform corrosion rates, typically less than 0.05 mm/year in quiet seawater.

Pitting & Crevice Corrosion: Significantly more resistant than many stainless steels, especially under stagnant or low-flow conditions common in flanges, joints, and submerged structures.

Galvanic Corrosion: While cathodic to steels, its performance is predictable, and it's often used strategically. Careful design is still required.

Stress Corrosion Cracking (SCC): Most common aluminum bronze alloys exhibit very high resistance to chloride-induced SCC, a major failure mode for susceptible alloys.

Biofouling and Microbiologically Influenced Corrosion (MIC) Resistance: Copper ions released from the alloy surface create an environment toxic to many marine organisms. This inherent property:

Reduces macro-fouling (barnacles, mussels) compared to inert materials like titanium or high-nickel alloys.

Inhibits the growth of sulfate-reducing bacteria (SRB) and other microbes responsible for MIC, a significant concern in pipelines, heat exchangers, and submerged equipment.

Erosion and Cavitation Resistance: The combination of high strength and the tenacious oxide layer grants Aluminum Bronze Plate excellent resistance to:

Erosion-Corrosion: Performs well in high-velocity seawater flow (e.g., pump casings, valve components, propulsor systems).

Cavitation Damage: Resistant to the destructive pitting caused by collapsing vapor bubbles, crucial for components like pump impellers, rudders, and hydrofoils.

Retained Mechanical Properties: Aluminum Bronze Plate maintains high strength, toughness, and fatigue resistance at ambient seawater temperatures. Its mechanical properties are generally not degraded by long-term seawater exposure, unlike some polymers or composites.

Critical Applications Leveraging Aluminum Bronze Plate Performance

The unique combination of properties makes Aluminum Bronze Plate indispensable in demanding seawater applications, such as:

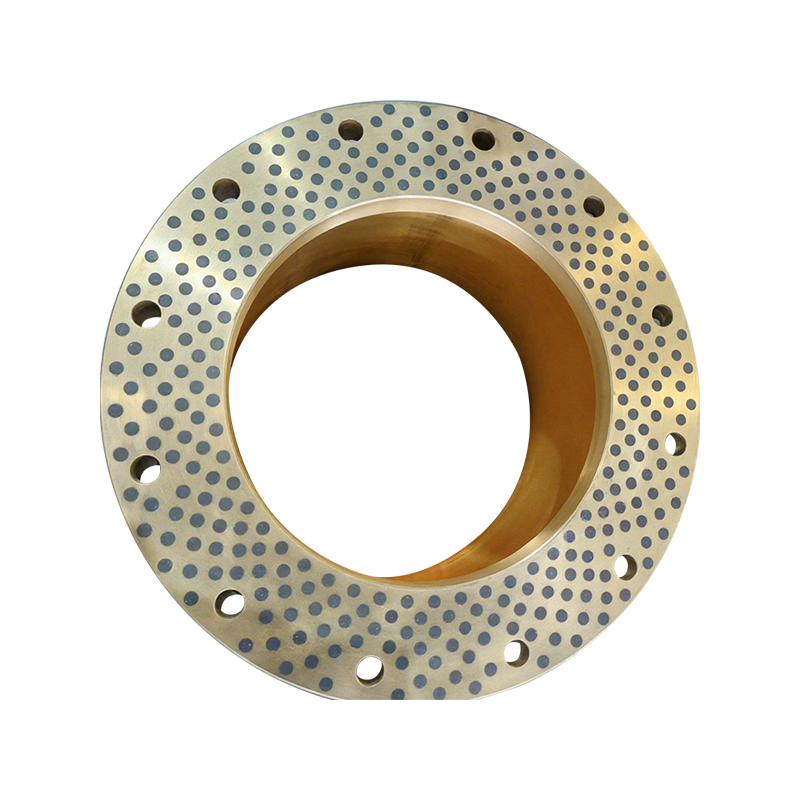

Marine Propulsion Systems: Propeller blades, hub assemblies, stern tubes, bearings, wear rings.

Seawater Piping & Valves: Pump casings, valve bodies, seat rings, flanges (especially under low-flow/crevice conditions).

Heat Exchangers & Condensers: Tubesheets, waterboxes, tubing (in specific designs).

Offshore Structures: Fasteners, bearing pads, hinge pins, splash zone components on drilling rigs and platforms.

Desalination Plants: High-pressure pump components, fittings exposed to raw and concentrated brine.

Ship Lock & Lifting Systems: Critical wear components, bearings, and gate seals.

Considerations for Optimal Performance

Alloy Selection: Specific grades offer optimized properties (e.g., C95500 for higher strength/wear, C95800 for castability/corrosion, C95400 for general use). Consult material specifications.

Fabrication & Welding: Requires specific procedures to maintain corrosion resistance in the heat-affected zone (HAZ). Post-weld heat treatment is often recommended.

Design: Avoid stagnant areas, ensure good flow, minimize crevices, manage galvanic coupling, and consider cathodic protection if necessary.

Water Velocity: While resistant, very high velocities (>5 m/s) or excessive turbulence can potentially accelerate wear; design accordingly.

In the harsh seawater environment, Aluminum Bronze Plate stands out due to its robust protective film, inherent resistance to biofouling and MIC, excellent mechanical properties, and proven performance against erosion and cavitation. Its reliability in critical components – from ship propellers and offshore platform hardware to desalination plant valves and ship lock systems – underscores its status as an engineering material specifically engineered for long-term durability in saltwater applications. When corrosion resistance, strength, and longevity in seawater are paramount, Aluminum Bronze Plate remains a technically sound and proven choice. Manufacturers specializing in high-end copper alloys, such as Yangzhou Yifeng Copper Products Co., Ltd., supply these vital materials for sectors including marine propulsion, offshore platforms, and heavy machinery where seawater performance is non-negotiable.

English

English 日本語

日本語 русский

русский Deutsch

Deutsch